I usually like to start with the quick and easy items on my to-do list, which is why it takes me forever to get to the big stuff. It’s a fault, and I recognize that, but nobody’s perfect. I tried to find the easy place to start this series of posts, but there seems to be only one logical place to begin – NFPA 105.

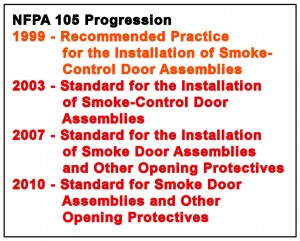

NFPA 105 has changed substantially since it’s inception in 1989. It was originally developed to address the fact that while a properly-installed fire door would adequately protect against the passage of fire, improvement was needed to inhibit the passage of smoke. Prior to the 2003 edition, NFPA 105 was a document that described “recommended practices” regarding smoke-control door assemblies. As with any recommendation, one could “take it or leave it” when it came to actually following the recommended guidelines. The document included valuable information about smoke, but it wasn’t a standard that would be referenced by a code and enforced.

NFPA 105 has changed substantially since it’s inception in 1989. It was originally developed to address the fact that while a properly-installed fire door would adequately protect against the passage of fire, improvement was needed to inhibit the passage of smoke. Prior to the 2003 edition, NFPA 105 was a document that described “recommended practices” regarding smoke-control door assemblies. As with any recommendation, one could “take it or leave it” when it came to actually following the recommended guidelines. The document included valuable information about smoke, but it wasn’t a standard that would be referenced by a code and enforced.

Beginning with the 2003 edition, NFPA 105 is a standard, and it’s now referenced by the IBC and several NFPA codes and standards (here’s an NFPA Journal article about the migration). Changes to the document reflect the effects of sprinklers on the pressures created by a fire, the stack effect in elevator hoistways, changes regarding installation, testing, and maintenance requirements, and the inclusion of smoke dampers.

You can purchase or view NFPA 105 on the NFPA website, but I’ve listed some of the high points below. One important thing to note before we get into the specifics is that some doors are smoke door assemblies, some doors are fire door assemblies, some doors are both, and some doors are neither. To figure out which requirements a door needs to meet, you would look in the building code or fire/life safety code, which I will be tackling shortly.

Administration: The requirements of NFPA 105 are intended to restrict the movement of smoke through door assemblies to maintain a tenable environment, providing life safety and protecting property from smoke. The standard addresses smoke door assemblies which restrict the passage of smoke at temperatures up to 400 degrees Fahrenheit (there’s currently no nationally-recognized standard for high-temperature smoke transmission), and the standard does not regulate elevator hoistway doors (Chapter 1).

Administration: The requirements of NFPA 105 are intended to restrict the movement of smoke through door assemblies to maintain a tenable environment, providing life safety and protecting property from smoke. The standard addresses smoke door assemblies which restrict the passage of smoke at temperatures up to 400 degrees Fahrenheit (there’s currently no nationally-recognized standard for high-temperature smoke transmission), and the standard does not regulate elevator hoistway doors (Chapter 1).

Testing: Smoke doors must comply with NFPA 105, and fire doors that are also smoke doors must comply with NFPA 80 as well as NFPA 105. Smoke door assemblies (including fire doors that are also smoke doors) shall have an air leakage rating not greater than 3 cubic feet/minute/square foot (0.9 m3/min/m2) of door opening when tested in accordance with ANSI/UL 1784, Air Leakage Tests of Door Assemblies, and the door shall bear an “S” label indicating compliance with this requirement (Chapter 4).

Installation: Smoke doors must be self-closing, or may be automatic-closing doors which close upon actuation of the smoke detection system. The clearance between the bottom of the door and the threshold or flooring is not required to have a seal. Louvers shall not be installed in smoke door assemblies “unless otherwise tested and listed” (Chapter 4).

Maintenance: Smoke doors shall be kept closed or shall be automatic-closing, and shall be equipped with latching hardware when required (more on that in later posts). Damage to smoke doors shall be corrected, and holes left by the removal of hardware shall be filled with steel fasteners or with the same material as the door and frame. When a door opening with a smoke door is no longer needed for use, the opening must be filled with construction equivalent to the wall construction (Chapter 5).

Inspections: Smoke door assemblies shall be inspected annually, and operated to confirm full closure. Damaged hardware and gaskets must be repaired or replaced, and door condition must be assessed. Written records of inspections shall be available for review by the AHJ, and shall be maintained for 3 years (Chapter 5).

From Annex A: “Where failure of a smoke door could result in greater life risk or property damage due to fire, administrative measures should be developed to provide protection prior to repair. Smoke doors are of no value unless they are properly maintained and are closed at the time of fire. Damage or impairments that affect the proper operation of smoke door assemblies should be corrected immediately. To ensure this, a periodic inspection and maintenance program should be implemented and should be the responsibility of the property management.

Closing/Blockage: Smoke doors may not be wedged or blocked in the open position. Self-closing and automatic-closing devices shall be maintained in good working order, and paint accumulation shall not inhibit the free closing of the door (Chapter 5).

Annex A contains some interesting background information about smoke and smoke control. Click here if you think you can handle it.

And if you STILL haven’t had enough…

A CFD Study of Air Leakage Through Door Assemblies for Smoke Control (2009)

Estimating Air Leakage Through Doors for Smoke Control (1990)

Performance of Unit Entry Doors When Exposed to Simulated Sprinkler Controlled Fire (2002)

You need to login or register to bookmark/favorite this content.

Lori,

I cannot find any code that says smoke doors have to be inspected annually, can you tell me were I can find this information.

Hi Terry –

It is in Chapter 5 of NFPA 105. One thing to watch out for is that not all “smoke doors” are required to comply with NFPA 105. There are lots of doors that people call smoke doors, but most of them are in locations where the codes do not reference NFPA 105. For example, most doors to patient rooms in health care facilities are required to provide an effective barrier to limit the transfer of smoke, but they don’t have to comply with NFPA 105.

– Lori