I received this photo the other day and I knew it was the perfect opportunity to talk about application-specific closers vs. universal closers.

I received this photo the other day and I knew it was the perfect opportunity to talk about application-specific closers vs. universal closers.

The closer in the photo is an LCN 4041-Cush, and because of the Cush arm (built-in stop) it is supposed to be installed on the push side of the door. I can’t tell why it wasn’t installed on the push side…it doesn’t look like there was a special frame detail, but for some reason it was installed on the pull side which required a special bracket that the installer made or procured from somewhere.

Installing it this way made the built-in stop ineffective since the arm never contacts it, and I’m sure the unconventional arm geometry affects the closing force or backcheck. There’s also the possibility of premature seal failure and fluid leakage due to stress on the pinion shaft from the angle of the arm. I’m surprised the closer cover and wall haven’t been damaged by the cover contacting the drywall reveal, but in time I’d expect to see evidence of this. (As Eagle-Eye Bob Caron pointed out, the closer cover has paint on it so apparently someone opened the door while the paint was wet and it touched the drywall. Maybe Eyal can go back in a year and report on the condition.)

The LCN 4041 is a universal closer, which means that it is non-handed, and can be mounted 3 different ways – hinge side, top jamb, or parallel arm mount. The benefit of a universal closer is the flexibility it offers – one closer can be mounted in multiple ways and handle various door/frame conditions. When a specific arm is specified with a universal closer, it limits the mounting location. For example, a universal closer with an EDA, Cush, or Spring-Cush arm can only be mounted parallel arm (push side).

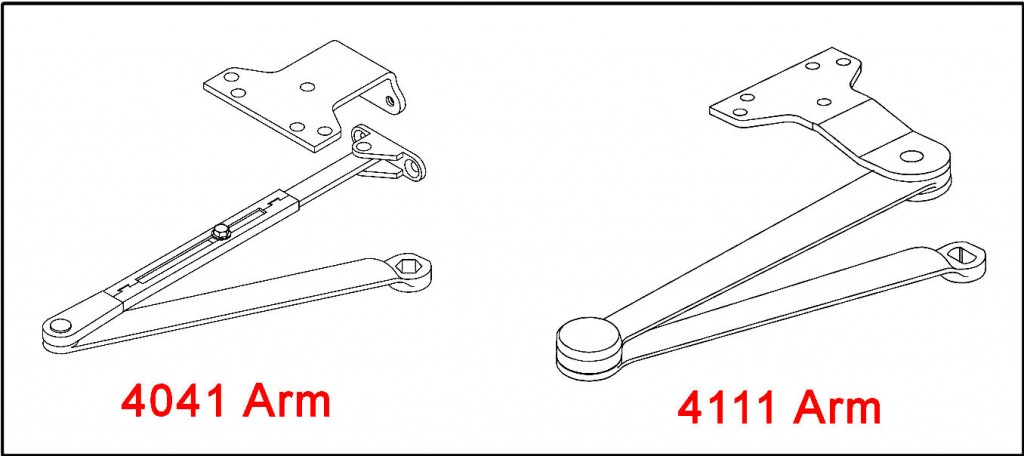

When I’m writing a specification, I typically use application-specific closers. These closers are designed to be mounted in a specific location and don’t have the flexibility of a universal closer, but they often cost less and there’s a greater likelihood that the installer will mount them on the correct side of the door. In my opinion, the most important benefit of the application-specific closer is the arm. The standard arms for the 4041 (universal) and 4111 (application-specific) closers are pictured below. The 4041 arm has to be adjustable with a separate parallel arm shoe in order to accommodate the three mounting styles. Because the 4111 is only used as a parallel arm closer, it has a solid arm with a permanently-attached shoe.

For more information about closer mountings, refer to this post.

Graphics courtesy of LCN Closers. Photo courtesy of Eyal Bedrik of Entry Systems Ltd (who was not responsible for this installation). Thanks Eyal!

You need to login or register to bookmark/favorite this content.

Lori writes: ” I’m surprised the closer cover and wall haven’t been damaged by the cover contacting the drywall reveal, but in time I’d expect to see evidence of this.”

It does appear that the cover made contact with the wall after the wall was freshly painted. Isn’t that a paint stripe on the cover?

You’re right! My brain processed that as a reflection but when I just zoomed in and looked at it, it IS a paint stripe!

It is interesting how we have seen LCN mounted from different levels of contractors and even if the 4111 is used they can find a different way to mount(as seen here). I think this was touching the frame as the paint tells all. Not sure why the new paint is there or was it from touching up the damage or is this a new site and just got painted as the cover is not damaged. The latching section is not in use as the timing is out that much with this mount. You said it as the seal will not last long but it will be a race between the cover or seal?

Robert

I’m guessing the cover would lose that race.

I have a customer who has a set of exterior “bifold” doors (hinge jamb, hinge, door, hinge, door)that swing out. Is there a closer out there that could mount to the stationary door to keep the active door closed? There will be times when the stationary door is opened so I can’t mount a closer on the frame head as this will not allow the stationary door to ever be opened without taking it off.

Hi Paul –

I can’t picture your application…if you want to send me a sketch I will take a look – lori.greene@allegion.com.

– Lori