For exterior pairs I prefer to use rim panic devices with a removable mullion, but in some cases surface-mounted vertical rod devices are specified and supplied. When vertical rod devices are used on cross-corridor doors, I often specify them “Less Bottom Rod” (LBR), but on exterior doors I specify them with both top and bottom latches for increased security.

For exterior pairs I prefer to use rim panic devices with a removable mullion, but in some cases surface-mounted vertical rod devices are specified and supplied. When vertical rod devices are used on cross-corridor doors, I often specify them “Less Bottom Rod” (LBR), but on exterior doors I specify them with both top and bottom latches for increased security.

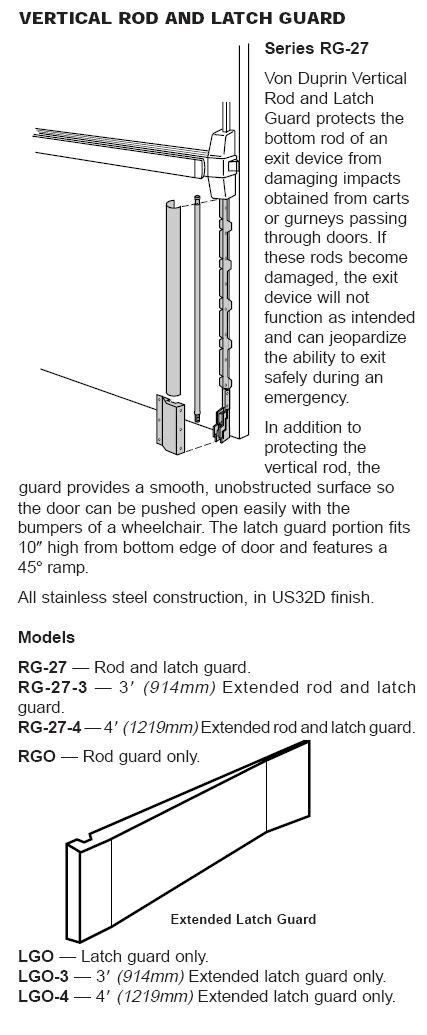

The bottom latch of a surface-mounted vertical rod device creates a problem when the area at the bottom of the door is supposed to be smooth and flush per the accessibility standards. One of our specwriters recently asked me about the use of the Von Duprin RG-27-3 extended latch guard, which slopes gradually toward the latch, eliminating the points where a wheelchair, crutch, or walker could be impeded by the projecting hardware. Let’s take a look…

Here’s the language from the 2003 edition of ICC/ANSI A117.1:

404.2.9 Door Surface. Door surfaces within 10 inches (255 mm) of the floor, measured vertically, shall be a smooth surface on the push side extending the full width of the door. Parts creating horizontal or vertical joints in such surface shall be within 1/16 inch (1.6 mm) of the same plane as the other. Cavities created by added kick plates shall be capped.

EXCEPTIONS:

1. Sliding doors.

2. Tempered glass doors without stiles and having a bottom rail or shoe with the top leading edge tapered at no less than 60 degrees from the horizontal shall not be required to meet the 10 inch (255 mm) bottom rail height requirement.

3. Doors that do not extend to within 10 inches (255 mm) of the floor.

The extended latch guard doesn’t technically meet this requirement because of the sentence about parts creating vertical and horizontal joints, but if I’ve learned one thing about codes it’s that they’re often written and modified without attention to the nitty-gritty of hardware. Read on…

Here’s the text from the A117.1 Commentary:

This provision is intended to assist people who will be attempting to open a door from the “push” side of the door. Some persons with disabilities push against doors with their chairs or walkers to open them. Applied kick plates on doors with closers reduce the required maintenance by withstanding abuse from wheelchairs and canes. If a door is provided with a smooth surface (one with no more than 1/16 inch [1.6 mm] variation), a user can be assured that the door will slide along the user’s foot plates, the leg rest of a wheelchair or the bottom of a walker or crutch that is being pushed against the door without catching. A vertical bar or rod on the latch side of a door is likely to interfere with the opening of a door when the feet or a footrest are pressed against a door to open it [see Commentary Figure C404.2.9(a)]. In addition to the door stop indicated in the commentary figure, common errors are hardware that extends the full height of the door or panic hardware with the vertical rod below the hardware on the outside face of the door. Hardware must stop at least 10 inches (255 mm) above the floor. A plate covering the rod in accordance with Exception 4 could possibly resolve some issues.

This provision is intended to assist people who will be attempting to open a door from the “push” side of the door. Some persons with disabilities push against doors with their chairs or walkers to open them. Applied kick plates on doors with closers reduce the required maintenance by withstanding abuse from wheelchairs and canes. If a door is provided with a smooth surface (one with no more than 1/16 inch [1.6 mm] variation), a user can be assured that the door will slide along the user’s foot plates, the leg rest of a wheelchair or the bottom of a walker or crutch that is being pushed against the door without catching. A vertical bar or rod on the latch side of a door is likely to interfere with the opening of a door when the feet or a footrest are pressed against a door to open it [see Commentary Figure C404.2.9(a)]. In addition to the door stop indicated in the commentary figure, common errors are hardware that extends the full height of the door or panic hardware with the vertical rod below the hardware on the outside face of the door. Hardware must stop at least 10 inches (255 mm) above the floor. A plate covering the rod in accordance with Exception 4 could possibly resolve some issues.

To be effective, a kick plate must cover the door width minus approximately 1 inch (25 mm) on each

side. It should start about 1 inch (25 mm) above the floor and go up to a height of 10 inches (255 mm)

from the floor [see Commentary Figure C404.2.9(b)]. This range will allow for the most common height settings for wheelchair foot plates. The requirement that cavities be capped will typically be applied when the kick plate is added onto a glass or panel door and the bottom rail of the door is less than 10 inches (255 mm) in height.

After reading the Commentary and speaking with someone from the ICC and some of my code official pals, I think that for doors where a surface-mounted vertical rod device is unavoidable, the extended latch guard would meet the intent of A117.1 because it would allow someone to push against it to open the door. Keep in mind that I have no authority whatsoever, and it would be up to the AHJ whether this is an acceptable solution. Another option would be to equip the door with an automatic operator, because then there’s no need to push on the bottom of the door. It’s interesting to note that the standard doesn’t mention that this requirement is relevant to manually-operated doors, but based on the Commentary, that seems like the case.

What do you think??

Thank you to Wayne Ficklin for sending me these photos!

of a walker or crutch that is being pushed against

the door without catching. A vertical bar or rod on the

latch side of a door is likely to interfere with the opening

of a door when the feet or footrest are pressed

against a door to open it [see commentary Figure

C404.2.9(a)]. To be effective, a kick plate must cover

the door width, less approximately 2 inches (50 mm),

up to a height of 10 inches (255 mm) from the floor

[see commentary Figure C404.2.9 (b)]. This range

will allow for the most common height settings for

wheelchair foot plates.

The sentence requiring that cavities be capped will

typically be applied when the kick plate is added onto

a glass or panel door and the bottom rail of the door is

less than 10 inches (255 mm) in height.

You need to login or register to bookmark/favorite this content.

Lori,

Several comments and a question:

– This is a great and timely topic that I think most of us have overlooked.

– The 2010 ADAAG (not enforceable until March 2011) has almost this exact same language about the door surface. Once this takes effect nationwide, there needs to be a concrete solution for this condition. Unfortunately the Federal government is the AHJ and it is nearly impossible to get a binding interpretation from them.

– What is the height of the extended latch guard?

Thanks, ED

Hi Ed –

The earlier edition of the ADA didn’t include this requirement, and even though it has been in A117.1 for a long time, not a lot of people knew about it. According to the installation instructions for the extended latch guard, the height is 12″. I’m sure this is because the requirement used to be for a 12″ high smooth surface, vs. the current requirement for a 10″ high smooth surface.

There are lots of little issues like this that I’m trying to address via the blog, to get some consensus and create a resource for us to point to when we need to clarify something that the codes don’t address specifically. Long-term, I’ll try to introduce some changes in the codes, but it’s a very long process so the blog is an interim solution.

a bit misleading in the title.. surface vertical rod guard might be more fitting…