Almost every week someone asks me about the clearance behind door pulls. Many manufacturers’ catalogs show certain pulls with a symbol indicating that they are accessible, and other pulls without the symbol. About 10 years ago I called the Department of Justice (ADA), the International Code Council (CABO back then), and the Massachusetts Architectural Access Board (521 CMR) to get the real scoop. All 3 agencies told me that there was no specific dimension required for clearance behind a door pull. I was recently asked this question about a cabinet pull, so I made all 3 calls again to make sure I wasn’t missing something. I was again told that you need to be able to slide a flat hand behind the door pull, and to open the door without gripping the pull. During both research projects I asked about a closed fist and was told that the clearance was not required to be large enough for a closed fist.

Almost every week someone asks me about the clearance behind door pulls. Many manufacturers’ catalogs show certain pulls with a symbol indicating that they are accessible, and other pulls without the symbol. About 10 years ago I called the Department of Justice (ADA), the International Code Council (CABO back then), and the Massachusetts Architectural Access Board (521 CMR) to get the real scoop. All 3 agencies told me that there was no specific dimension required for clearance behind a door pull. I was recently asked this question about a cabinet pull, so I made all 3 calls again to make sure I wasn’t missing something. I was again told that you need to be able to slide a flat hand behind the door pull, and to open the door without gripping the pull. During both research projects I asked about a closed fist and was told that the clearance was not required to be large enough for a closed fist.

I also consulted the ADAAG Manual, which is not a code or standard but which explains the ADA requirements in more detail:

Door Hardware (4.13.9)

Hardware used to operate doors, including handles, pulls, latches and locks, must have a shape that is “easy to grasp with one hand” and does not require tight grasping or pinching, or twisting of the wrist to operate (i.e., no round knobs). Various types of hardware are acceptable although those that can be operated with a closed fist (levers, push bars) or a loose grip (pull handles) accommodate the broadest range of users. Thumb turns, which are operated with simultaneous hand and finger movement, require a high degree of dexterity and coordination and are not recommended. When sliding doors are fully open, the hardware must be exposed and usable from both sides.

So, in my opinion, pulls that allow your hand to slide though are acceptable regardless of the clearance dimension. Pulls that require you to grip them are not. The gray area is whether a particular pull needs to be gripped to effectively open the door. For example, the “batwing” pull for a Von Duprin 33/35 device doesn’t seem like it would meet the intent of the requirement. Ditto on the flat extruded aluminum storefront door pulls that have almost become extinct. The photo to the right shows a pair of doors with one of the flat pulls and one newer pull. I’m not sure if they were trying to make one door accessible or just replace a broken or missing pull, but they were obviously on a tight budget.

A word of caution though…some code officials rely on manufacturers’ catalogs for information on which products are considered accessible. We ran into this with thumbturns. None of the accessibility standards define what size an accessible thumbturn needs to be, but because a catalog showed a larger thumbturn marked with the symbol, the code official required that all of the thumbturns on the project be changed to the larger type.

.

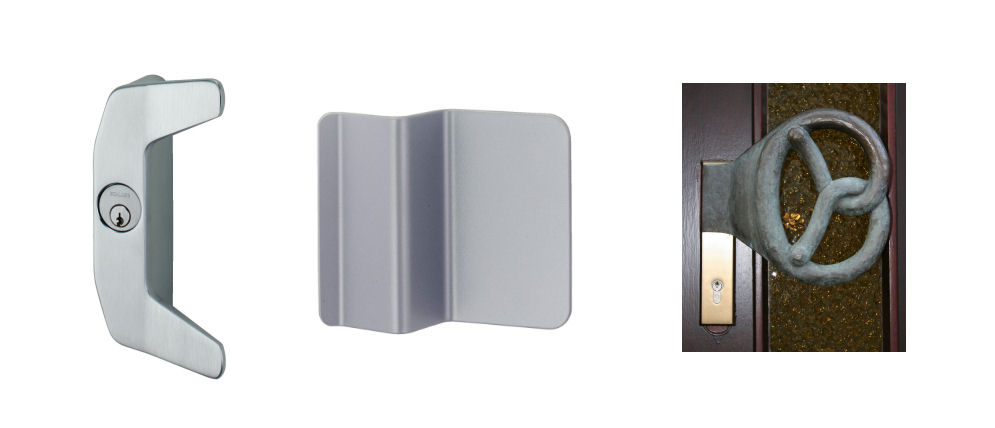

Here are a few of the thousands of accessible pull designs:

.

In my opinion, these pulls are not the best choices for accessible doors:

.

These pulls from artfactory.com are pretty cool, but again, not the best choices for accessible doors:

You need to login or register to bookmark/favorite this content.

What about recessed pulls in FRP doors? It would seem they definately would be a challenge to the disabled…

Many flush pulls aren’t considered accessible, but they’re still very common on FRP doors. They’re more vandal-resistant, but not easy for someone with a disability to use.

– Lori

We use a 1-1/2″ grip clearance (handrail code) for basic design. It does not work with every design, but fits 95% of applications quite nicely.

Hi Lori,

For a cabinet, are recessed door pulls allowed from an accessibility standpoint or are just pulls that project off the cabinet?

Hi Robin –

I don’t get into cabinet hardware much, but I took a quick look through A117.1. In Chapter 9 – Built-In Furnishings and Equipment, section 905.4 – Storage Facilities requires operable parts to comply with section 309. Paragraph 309.4 requires operation with no tight grasping, pinching, or twisting of the wrist, and a maximum of 5 pounds of force.

The standard doesn’t include prescriptive requirements for pulls, but many flush pulls for cabinetry would not be operable without tight grasping, etc. I think a wire pull would be a safer bet, although the AHJ may allow something different.

– Lori

Hi Lori,

First let me thank Tom Breese and idighardware for the wonderful post you recently published on your site about us. It is very much appreciated, please do let Tom know.

I loved the clear analysis of your piece above concerning door clearance and I have checked some of your recent posts but wanted to see if you knew of any code changes that impact what you have written. This can be a thorny topic so I do appreciate it when I come across truly helpful articles like yours.

Any input you have would be appreciated.

Thank you.

Anne