Every so often, I wonder what I’m going to write about on this blog after I’ve covered all of the code requirements for doors and hardware. I mean, it’s a very specific subject area so at some point I could run out of questions. And then something comes up that I’ve never looked into, and I stop wondering. There will always be more questions. If hardware was easy, it would be called “easyware,” right? 🙂

Last week, a life safety consultant asked me about hospital stops, because a hospital had been cited for having stops that weren’t continuous on their fire-rated frames. Huh. It’s been a long time since I’ve even thought about hospital stops, or terminated stops as they’re also called. I know we covered them back in hardware school, but they’re not something you see every day (unless you work in a hospital).

Last week, a life safety consultant asked me about hospital stops, because a hospital had been cited for having stops that weren’t continuous on their fire-rated frames. Huh. It’s been a long time since I’ve even thought about hospital stops, or terminated stops as they’re also called. I know we covered them back in hardware school, but they’re not something you see every day (unless you work in a hospital).

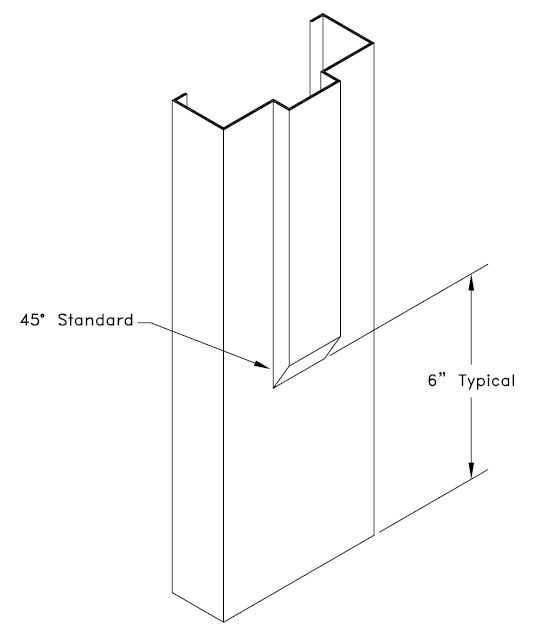

For those of you who haven’t gone to hardware school, a hospital stop is a modification to a door frame, where the stop is terminated above the floor – usually at 4″, 6″, or 8″ from the bottom of the frame. The bottom of the stop is closed at a 45-degree or 90-degree angle. The purpose is to make it easier to clean that area of the floor without the extra corners to catch debris, and to avoid getting cart/bed wheels caught on the stop.

Should the facility be cited for having stops that aren’t continuous? Hospital stops aren’t specifically covered by any codes that I know of, so I would refer to the frame manufacturer’s listings. Steelcraft’s UL certificate of compliance specifically mentions that terminated stops are permitted, and many other manufacturers offer them as well. The UL Outline of Investigation for Fire Door Frames (UL63), includes the following reference to terminated stops:

7.23 Terminated stops

7.23 Terminated stops

7.23.1 Single-unit type, pressed-steel frames and two-section type frames may be provided with terminated stops. See 7.4.3. The stops shall terminate not more than 6 inches (152 mm) above the floor line and shall be closed with a 45- or 90-degree angle.

7.4.3 Stainless-steel spats not over 8 inches (204 mm) in height may be provided on the bottom of the hinge and/or strike jambs.

The frame manufacturer will be able to confirm whether their procedure allows hospital stops, and what the maximum height is. If any hollow metal manufacturers want to chime in and tell us what your procedure calls for, feel free!

UPDATE: I received the following details from Rachel Smith of Karpen Steel, who confirmed that the maximum height allowed by their procedure is 6″ measured to the bottom of the stop, and they are able to do a version of a hospital stop on a labeled double egress frame.

Single rabbet with 45 degree hospital stop

Double rabbet with 45 degree hospital stop

Double egress with 90 degree hospital stop

Thank you to Brad Keyes of the Greeley Group for the photo, Kurt Roeper of Ingersoll Rand Security Technologies for the UL help, and Rachel Smith of Karpen Steel for the detail drawings.

You need to login or register to bookmark/favorite this content.

Would they also be compliant for NFPA 105 for smoke?

Hi Jerry –

I read through NFPA 105 again looking for anything that might affect the use of hospital stops, and the only thing I came up with was the UL 1784 requirement. Smoke doors and certain rated doors have to be tested to this standard for air infiltration. The fact that there’s no stop or gasketing at the bottom of the jambs could impact those test results somewhat, but I don’t think it would be enough of a problem that the air infiltration requirements couldn’t be met. If you think about a fire test or an actual fire, the bottom of the door isn’t where the smoke is typically passing through.

– Lori

Lori,

First, let me say thank you for my morning continuing education sessions.

In response to your comment above about the allowable height for hospital stops versus the allowable height for spats…

I’ve haven’t read UL 63, (Heck, I don’t think I’ve even heard of it!) so maybe section 7.4.3 is specifically in reference to hospital stops. However, I have seen, in at least two HM manufacturers catalogs, options for spats on frames without hospital stops. So, codes being codes, maybe they are just covering all the bases.

Hi Ken –

You’re welcome! 🙂

I think you’re right…as I replied to Deb’s comment, it just seems weird that the standard refers to a section that talks about 8″ high spats when the hospital stops are limited to 6″ high. I’m going to ask for some more information from a couple of manufacturers, and I’ll ask about the maximum height allowed per their UL procedures.

– Lori

What’s a “spat”?

Hi Jim –

Spats are usually made of stainless steel, and they wrap the bottom of the frame for added protection. I found some here: http://absupply.net/door-frame-components-spats.aspx.

– Lori

I’m not a manufacturer, but I love Hollow Metal frames!! My very favorite thing! LOL! This is a really good post. First…spats and hospital stops are not the same thing. You can have either one or both–they are not required together.

I always thought the hospital stops were measured on the “flat” part, i.e. 6″ was to the bottom of the terminated stop (the 45* closure being part of the stop). However, one of your larger competitors shows that the hospital stop is measured to the end of the stop which is OK if it’s a 90* stop but if it’s 45*, the 45* closure is included in that 6″ (so the flat part would only be 5-3/8″). I would be interested to know if all manufacturers measure it this way.

In the standard hospital stop, you still have the allowable 1/8″ gap between the door and frame. I would think this would only be an issue in a smoke partition. NFPA 101 (2009) does not require positive latching on smoke barrier cross-corridor doors (20.3.7.10). But it does say “…stops shall be required at the head and sides of door frames in smoke barriers” (20.3.7.13) It does not state specifically that those stops must be continuous down to the floor. Considering the clearances allowed in smoke doors, I don’t think a lack of 4″-6″ of stop at the bottom of the frame is significant. Smoke rises, right? (Think also of the 3/4″ clearance) So, IMHO, the hospital in question should not have been cited.

Now what about double egress? Can you have hospital stops on DE and maintain the label? Not only do you terminate the stop, but you must also fill (kind of a reverse termination) the other side of the frame. You still have the hospital stop clearances but you have added a “filler” on the frame to close what would have been a 5/8″ gap. I have done this many times on non-labeled DE but never on UL since I haven’t been able to confirm it’s been tested that way. Have any manufacturers tested this?

Great post, Lori! Thanks!

Hi Deb –

I know that spats and hospital stops aren’t the same thing, but it seemed odd to me that the UL standard would refer to a section talking about 8″ maximum spats when the maximum for hospital stops per that standard is 6″. I guess it means that you can have 8″ spats on a frame with regular stops, and 6″ spats on a frame with hospital stops.

I’m not sure how all the manufacturers measure their hospital stops but I’ll try to get some input from a couple. I’ll also ask about hospital stops on double egress frames.

– Lori

Don’t test procedures UL10C & UL1784 allow the bottom 6″ of the door to be tapped shut? If this is still the case then a hospital stop would pass the [S]UL 1784 standards. Because there is a 400 degree temperature test as part of UL1784 they essentially are fire rated doors. The only exception is that in many jurisdictions with older NFPA 101 codes still in place, the smoke partition doors needing to meet UL 1784 do not need self latching hardware. The newest version of NFPA101 gets this corrected and all smoke partition doors need to be self latching. There are multiple manufacturers that offer a [S] UL1784 only label, not to be confused with a fire door label….. right.

Yes, UL 1784 allows the bottom 6″ to be sealed, so the lack of a stop on the bottom 6″ inches of the frame shouldn’t be an issue for air infiltration.

UL 1784: 5.4.5 In order to obtain information on the extent of air leakage at the ungasketed bottom gap of a test sample, an artificial seal may be applied to the bottom 6 inches (152.4 mm) of the test sample. The artificial seal may be any material, such as an impermeable sheet or tape.

Single rabbet with 45 degree hospital stop Shows a double rabbet profile.

Double rabbet with 45 degree hospital stop Shows a single rabbet profile.

Double egress with 90 degree hospital stop Is actually a single rabbet profile at the bottom. Pointless.

Details like these are often overlooked and can turn into costly rejections or replacements.

More importantly, Projects not being completed on time.

When you get tired of your supplier overlooking things, Give me a call. You can find me on our site.

jk

Btm 6″: if sound or light are concerns, could possibly use a better-quality adhesive-applied seal to the edge of the door where terminated frame stops are used.

Good point!

How about hospital stops on a lead lined door?

Hi Josh –

That’s a good question but it’s one that a physicist would have to answer. Depending on the equipment, hospital stops may or may not be acceptable. It will vary by project.

– Lori

Lori-

That was my assumption as well, that the physicist would need to have input. Thank you for following up.

We have a situation where they want to essentially fill the void left by the hospital stop in a door frame for Acoustic purposes. Any one ever dealt with that problem? My proposition was to custom fabricate a piece to attached where the 6″ void is left and screw it into the actual stud behind the door jambs. Anyone have any thoughts?

Would that defeat the purpose of the hospital stop?

Yes – filling in the area where the stop has been cut out would defeat the purpose of the hospital stop – especially if the filler extends all the way to the floor. But maybe the acoustic needs trump the need for easy cleaning in this case.

– Lori

Anyone ever used a continuous hinge with terminated stops? Did you install the hinge the length it came or do you cut it to where the bottom of the terminated stop is?

Hi Paul –

I have never considered cutting the hinge short since the door and the frame rabbet both continue below the terminated stop, but maybe someone else has a different opinion.

– Lori

Lori, just to clarify, regardless of the height of the stop, the maximum permitted 1/8″ clearance on the pull side of the door between the edge of the door and the frame must still be met on a labeled fire door, correct? Thanks, Rodney

Hi Rodney –

NFPA 80 requires 1/8-inch clearance on the pull side at the head and jambs for wood doors, and allows 3/16-inch max for hollow metal doors. The 2016 edition of NFPA 80 allows up to 3/16-inch clearance for 20-minute wood doors, stile-and-rail doors, and decorative-laminate-faced doors installed in hollow metal frames. These limits also apply to the clearance at the meeting stiles.

– Lori

If you need a door gap gauge to check your fire rated door for compliance with NFPA 80 swing by and check this one out from All Things Inspector via this link https://allthingsinspector.com/purchase-door-gap-gauge-now/