If you’re not in the habit of reading NFPA 80 cover-to-cover each time it is updated, this one might have slipped by you. It’s an important change. Let’s start with a (trick) question:

What is the maximum hole diameter that can be drilled on a fire door assembly in the field, as a job-site preparation for surface-mounted hardware?

I think I just heard a lot of you say that the maximum diameter of the allowable holes is 1 inch, with the exception of holes for cylinders (which may be larger than 1 inch). While this limitation is still stated in NFPA 80 – Standard for Fire Doors and Other Opening Protectives, the 2016 edition includes a new paragraph:

4.1.3.2.3 Holes exceeding a diameter of 1 in. (25.4 mm) shall be permitted for surface-applied hardware installed in accordance with the door manufacturer’s listing and the hardware manufacturer’s listing.

Could that be true? Holes larger than 1-inch diameter may be allowed to be drilled in the field? I checked the NFPA 80 Handbook (you can buy a copy here), and it explains that electrified hardware frequently requires holes larger than 1-inch diameter. While paragraph 4.1.3.2.3 does not state that only holes for electrified hardware may be larger than 1-inch diameter, electrified hardware was likely what motivated the change.

Could that be true? Holes larger than 1-inch diameter may be allowed to be drilled in the field? I checked the NFPA 80 Handbook (you can buy a copy here), and it explains that electrified hardware frequently requires holes larger than 1-inch diameter. While paragraph 4.1.3.2.3 does not state that only holes for electrified hardware may be larger than 1-inch diameter, electrified hardware was likely what motivated the change.

Note that there are other limitations in NFPA 80 that apply to these holes. For example, NFPA 80 allows “round holes” and the common interpretation is that the larger holes described in 4.1.3.2.3 are still required to be round. And the holes must be allowed by the listings of the door manufacturer and the hardware manufacturer. When the hardware manufacturer’s installation instructions for a listed product show a field preparation for a hole, those installation instructions and templates are part of the listing file. This establishes that the hardware manufacturer’s listing allows the field prep. But the door manufacturer’s listings must also allow the prep, and confirming this could take a little extra legwork.

The 2016 edition of NFPA 80 is referenced by the 2018 editions of the model codes, so technically this change would apply in jurisdictions that have adopted a code referencing the 2016 edition of NFPA 80. With that said, it’s possible that the AHJ could allow the larger field-drilled holes as an equivalency.

Have you applied this change in the field? Do you have any insight or questions about job-site preparations on fire door assemblies?

You need to login or register to bookmark/favorite this content.

What types of common hardware would you interpret to be “surface-applied”?

If we are talking about cylindrical or mortise type locks, I would think these are contained within the door, not surface-applied.

I suppose it depends upon how you define “surface-applied”.

If mortise or cylindrical are not surface-applied, what is a common example of a surface-applied piece of hardware which would require a hole larger than 1″ (cylinders excepted)?

Great question, Tom! I’ll write a follow-up for Thursday! 🙂

– Lori

It most likely is in reference to typical Fire Rated exit devices. Panic exit hardware. As with all panic hardware they should be thru-bolted but seldom are as most installers not familiar with these devices opt for speed during installation . Thru bolting takes time .

Hi David –

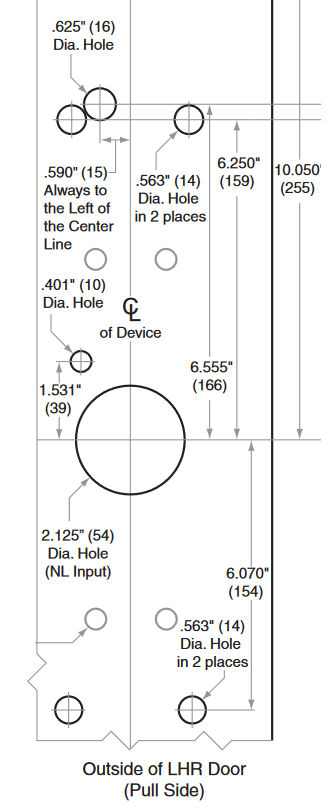

An example is the template that I included a partial image of…when retrofitting this electrified trim on an existing prep for fire exit hardware, it requires a new 2 1/8-inch hole. This field prep is shown in the installation instructions, which are covered by the product listings, so it is acceptable to do the prep in the field as long as the door manufacturer’s listings allow it.

– Lori

Lori:

Most of the preps such as the AD prep shown above are on non-rated exterior doors. Again, you would more that likely have to replace any other existing fire-rated door, as the label on the door was only for the hardware that was installed at the time. In a lot of cases, this may have been from a number of years ago. If hollow metal, reinforcing would not be in the proper places, and again a new door should be used. If wood then again, the door would not have been tested with the larger blocking required to install the pictured template.

Hi Sig –

The original question that motivated me to look further into this paragraph was for a project where more than 100 of the AD trims were being retrofitted. Some of these doors are fire doors, some are not. The doors have existing panic hardware or fire exit hardware, and are labeled correctly for this hardware, with the proper reinforcing.

– Lori

Is there a Von Duprin rim fire rated panic that just takes round holes to prep. I am not aware of one. That is why I have to lean towards Allegion’s competition that is approved and fits over a standard lock prep. when I need to do a onsite modification to add a panic. The one that amazes me is the S and G 2890B with a 2740B when you get done I feel like I am looking at swiss cheese.

Hi Jay –

At the moment, our devices with trim require preps that are not round holes, but the engineers are aware that round holes are preferable, so fingers crossed for future changes.

– Lori