Last week I read a blog post called, “Excuse me, but your slip is showing,” from Constructive Thoughts, the blog of Sheldon Wolfe. I’m a sucker for a well-researched article on a code-related topic, so I sent Sheldon an email asking if I could reference his post here. Sheldon told me to have at it, but also said that it wasn’t very satisfying for him to write this type of article – where you research every angle and end up without a useful conclusion.

This happens to me quite frequently – I dig into the codes looking for a concrete answer, and in the end I may find that there is no prescriptive information in the codes, or the lack of familiarity with the nitty-gritty of hardware results in confusing language that is open to interpretation. In this situation I feel some level of accomplishment in confirming that there is no concrete answer, and then I add it to my wish-list for code changes to propose during the next code development cycle. And in the meantime, I try to establish some precedent that will help others make a sensible interpretation.

Sheldon’s article is about slip-resistance of flooring materials – here’s a little excerpt to get you started (read the rest here!)…

I don’t know how this issue has escaped me for nearly forty years, but I’m not alone. In that time, I have occasionally talked about coefficient of friction for floors, but I just discovered there has been no widely accepted standard for slip resistance. Not only that, but neither the IBC nor ADA define slip resistance, even though both require slip resistant floors and walkways.

How the heck is that possible? Think of all the very specific requirements in the building code. How did they miss this one? And think of ADA, with its Byzantine combination of Spock-like precision in some areas, and a “Take a guess and we’ll see you in court” approach to other requirements. How can it be that the good folks who write the ADA requirements know exactly what so many dimensions must be, but they have no idea what they mean by slip-resistant? It seems to me that not falling on your arse is a lot more important than a quarter inch difference in the location of a water closet, but this apparently – no, this obviously important performance characteristic has had no definition.

I love Sheldon’s description of the ADA, which is completely accurate in my opinion. 🙂

I remember going to National Guard Products years ago and learning about their slip-resistant surface, called SIA (“Slick It Ain’t”), so I checked out the NGP catalog to refresh my memory:

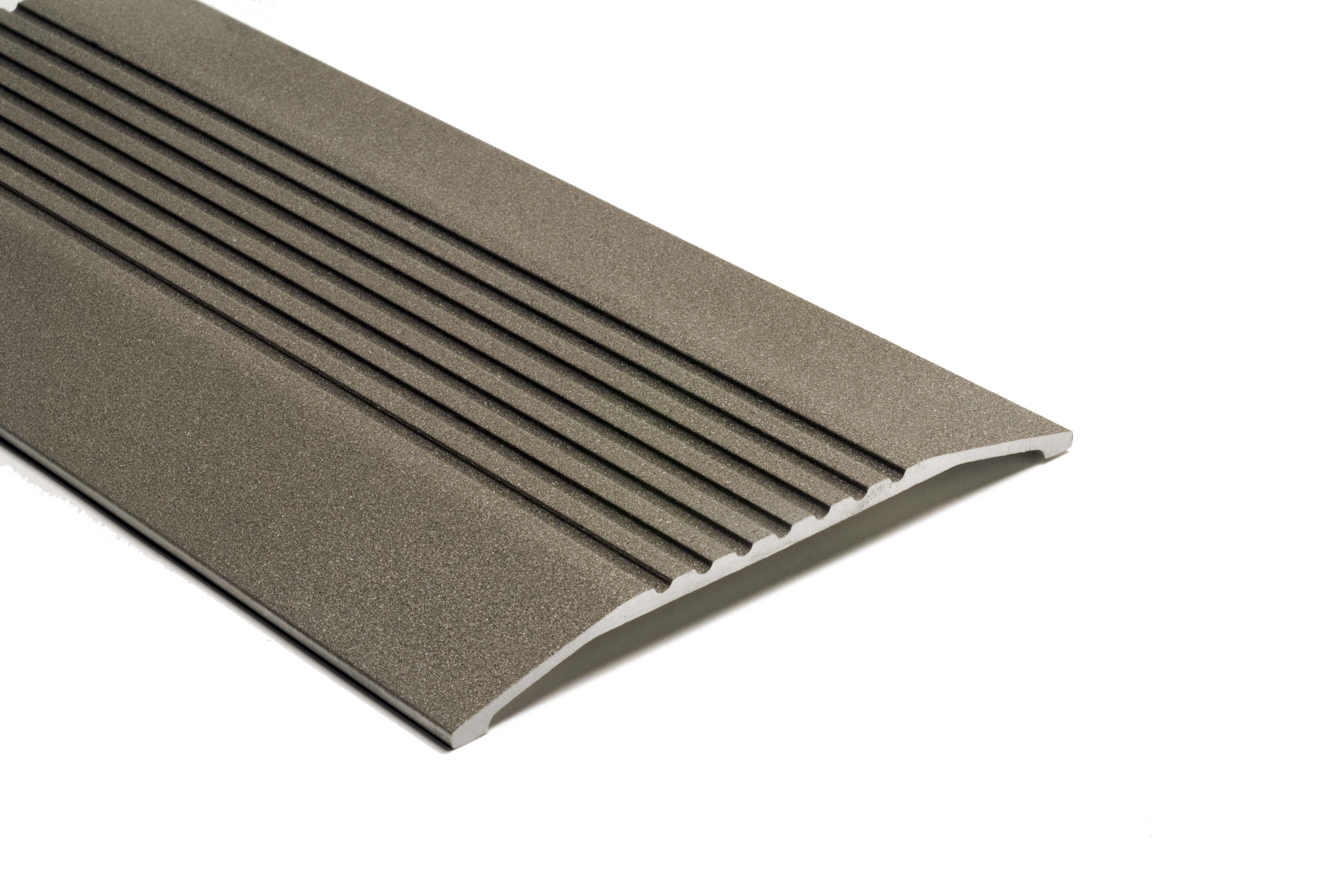

SIA (Slick It Ain’t) finish is our slip resistant textured surface, available on all thresholds up to 24” wide and on 818 aluminum cover plate up to 10” wide. Our SIA technology embeds bits of hot nickel and titanium into the surface of the threshold using a high pressure thermo-electrostatic process. It was originally developed for use on aircraft carrier decks. SIA finish is very durable and will not wear off. This results in a slip resistant surface that is similar to high grit sandpaper. Aluminum and Stainless Steel SIA finish thresholds are a pewter color. Architectural Bronze SIA finish thresholds are a brass color.

SIA (Slick It Ain’t) finish is our slip resistant textured surface, available on all thresholds up to 24” wide and on 818 aluminum cover plate up to 10” wide. Our SIA technology embeds bits of hot nickel and titanium into the surface of the threshold using a high pressure thermo-electrostatic process. It was originally developed for use on aircraft carrier decks. SIA finish is very durable and will not wear off. This results in a slip resistant surface that is similar to high grit sandpaper. Aluminum and Stainless Steel SIA finish thresholds are a pewter color. Architectural Bronze SIA finish thresholds are a brass color.

This finish, without a doubt, ain’t slick. But if slip-resistance isn’t defined in the codes, when should you specify or supply a finish like SIA? I asked Roger Skold of NGP, and here’s what he told me:

“Slip resistant finish should be used wherever a slip hazard is more likely. Wider and smoother surfaces and those with more slope are first by design, including wide smooth cover plates or thresholds, ramps (based on slope and width), and any type of threshold, plate or ramp that is being installed with possible exposure to moisture of any type. It really boils down to common sense and liability – use the non-slip finish to protect people crossing smooth, wide or increased slope surfaces to lessen the chance they may fall. They may still be at risk of a fall depending on their shoes and their balance.”

Without prescriptive code language, the best we can do is to use common sense and specify/supply slip-resistant products where we see an increased risk.

Where have you used slip-resistant thresholds and ramps?

Thank you to Sheldon, Roger, and also to Connie Pride of NGP for the photo!

You need to login or register to bookmark/favorite this content.

You have touched upon a sensitive topic for designers working in Public Transit and other high traffic situations. If one looks to ASTM there are many and varied tests as well as standards for slip resistance. this means that an AHJ must define what is both an acceptable standard and test. Looking across the pond to Europe, we see EN standards that define this in a much clearer fashion in particular with reference to ceramic tiles. The standards also look to applications for slopes and depth of tile profiles.

The largest issue with slip resistance is getting clear understanding between the needs for a cleanable surface and the required aggressiveness of the slip resistance. The more aggressive, the more difficult it is to keep clean. Finding the balance that suits both the image and legal concerns is a real challenge. I have run into complaints with surfaces that “ate” mops or abraded hands due to the aggressiveness of the finish down to concerns with mopping or cleaning three or more times per day.

The other concern that is starting to crop up is the life cycle of the aggressive or slip resistant finish. it is kind of like checking your tire treads for wear. the slip resistant finish needs to last for a reasonable length of time under the specific traffic conditions. Steel checkerplate is pretty durable but has a limited life in a high foot traffic situation. Similarly any slip resistant finish will need replacement as part of a regular life cycle assessment.

Here in Toronto we have a transit commission that uses tiles for the nosing or leading edge of stair treads with the body in terrazzo. the terrazzo is very durable but the nosing wears quickly and needs to be replaced often. An aggressive and durable porcelain product is now used and the nosing can be replaced quickly and easily if worn or damaged.

Thanks for the info John!

I’ve specified the SIA-type finish for thresholds on a school that otherwise had dark-bronze hardware, and the Owner had balked at the cost of oxidized & oil-rubbed thresholds. Dark-anodized aluminum finish is a terrible choice for well-trod thresholds: the finish scuffs away and we’re left with the warmth and beauty of raw aluminum mixed with the dark-anodized finish. The pewter type finish of the “SIA” is a better fit color-wise, but I got push-back for how dirty the thresholds had gotten with use — the finish grabs and holds dirt quite efficiently. Couldn’t win with that situation…

I’ve otherwise used the slip-resistant finish in pool areas.

I have not seen anything about threshold friction in door or hardware specs. I do know that the NFPA did specify a coefficient of friction for tread plate on fire trucks, and that is the closest I have seen to a spec for any walking surface. Fire truck tread plate was changed to make wet surfaces have better traction for wet rubber boots by knurling the tops of the diamond buttons on the tread plate. (file the fire truck info under useless info you will never need) I also seem to remember some history with friction pieces being added to steel ladders (like overhead crane access ladders)in an industrial location. It is still common to use steel or aluminum metal grating in overhead catwalks that has some added or modified edges for slip resistance. I have some old buried thoughts about stair tread edges and such, but I have never seen any threshold specs about texture or slip.

Over the past few years I have gone out of my way to specify the “SIA” none slip surface within my local market with very little push back on the added cost. When looking at the current legal ramifications if someone were to slip on a wet aluminum threshold surface, I believe it is money well spent.

Lori

Absolutely love the blog… This post was right on point… slip resistance is so super critical… thanks for sharing…

Thanks for writing another great article.

btw: You and your team do a fabulous job with this content…

Thanks Juliet! I don’t actually have a team – I produce all of the content and take care of the blog myself. I do have my man-behind-the-curtain, Robert Drake of Creekside Systems, who helps me when I want to make a structural change to the site (like changing the color from red to orange when we became Allegion). Beyond Robert, my “team” consists of all of the industry members who read my posts, add their comments, and make this a community effort. Go Team! 😀

Sheldon and I go a long way back on ADA requirements and specifications. There is no such think as a slip resistant surface, because anything that comes between the bottom surface of you foot or shoe that happens to be on that walking surface can be a contaminant that could be hazardous (per Dr. Alex Sacher)and could cause a slip, or trip and result in a fall. Being an accessibility consultant to architects and commercial property management companies, I do the best that I can that will show in court I specified the most tried and true Daubert proof, test method for slip resistance on walking surface. ASTM-D2047 with a 70 year experiential history legacy of reliability. You can use any tribometer and any test method, what it boils down to is what did you specify?

I specify Pemko skid resistant coated thresholds. The slip resistance especially affect crutches since they tend to create forces that push outward on the surface of smooth finished TH that could also be damp.