Last year as one of my projects neared completion, the architect called me to say that the bottom latches of the fire exit hardware were not long enough to reach the floor-mounted strikes. This is a pretty common problem because that clearance needs to be very tight for the latch/strike templating – sometimes as little as 1/4″ between the bottom of the door and the surface where the strike is mounted.

As I dug into it a bit, I realized that he had a bigger problem than I originally thought…someone at the architectural firm had changed the submittal to show a 1 1/8″ undercut on the doors, including the 16 fire-rated pairs in question. I have no idea how that made it back through the distributor and the door manufacturer but the doors were on-site and hanging. Now what?

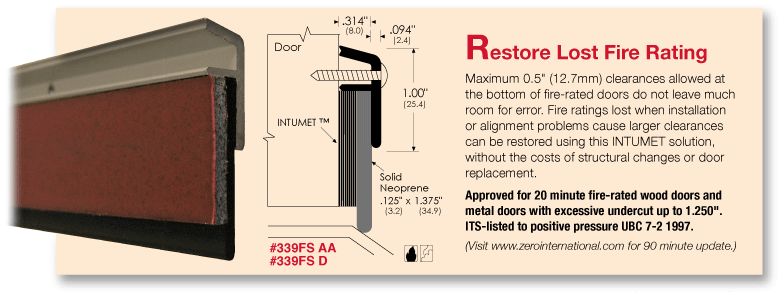

We worked out a solution with the AHJ, which involved changing to less-bottom-rod fire exit hardware and installing auxiliary fire pins, and adding thresholds to reduce the clearance at the bottom of the door. At the time, I had not seen the 339FS intumescent door sweep by Zero International. The product is currently approved for use on 20-minute wood or hollow metal doors, with clearance of up to 1 1/4″ – measured between the bottom of the door and top of the threshold or flooring material. Zero hopes to have approval for 90-minute doors in the near future.

Although NFPA 80 limits the door bottom clearance to 3/4″, the Equivalency section of the standard allows new, modified, or improved products that meet the intent of the standard. Until the new and improved products are addressed in the standard, the AHJ must be consulted for approval of the product equivalency.

Here is the Equivalency section from NFPA 80-2007:

1.4 Equivalency.

1.4.1* This standard shall not prohibit the development of new, modified, or improved devices that meet the intent of these requirements.

A.1.4.1 The development of fire doors and related devices is a continuous process; therefore, this standard is not always current. This standard is intended to be current only at the date of publication.

1.4.2 It shall be the responsibility of the manufacturer to furnish the information necessary to update the requirements

pertaining to such new and improved devices.

1.4.3 For devices not described in this standard, theAHJ shall request descriptive information from manufacturers that is provided by a testing laboratory concerning acceptable methods for satisfactory field installation based on fire tests and engineering studies for operation and maintenance considerations, where applicable.

Have you seen a similar solution for oversized clearance at the head and jambs of fire doors? Send me a link!

You need to login or register to bookmark/favorite this content.

Lori,

FYI, 45 – 90 minute fire rated wood doors with LBR typcially require special internal construction, like 5″ full height vertical blocking at lock rails. Varies per door manufacturer and per door height.

Hope these doors you changed were either HM or 20 min.

Dan Ferry, AHC

They were hollow metal, but that’s a good point. I will check with some wood door manufacturers and add to the post.