Someone asked me a question the other day and it turned out to be one of those “things that make you go hmmm…” The question was this:

Someone asked me a question the other day and it turned out to be one of those “things that make you go hmmm…” The question was this:

Would a surface mounted automatic door bottom with a sloped top be allowed by the accessibility standards?

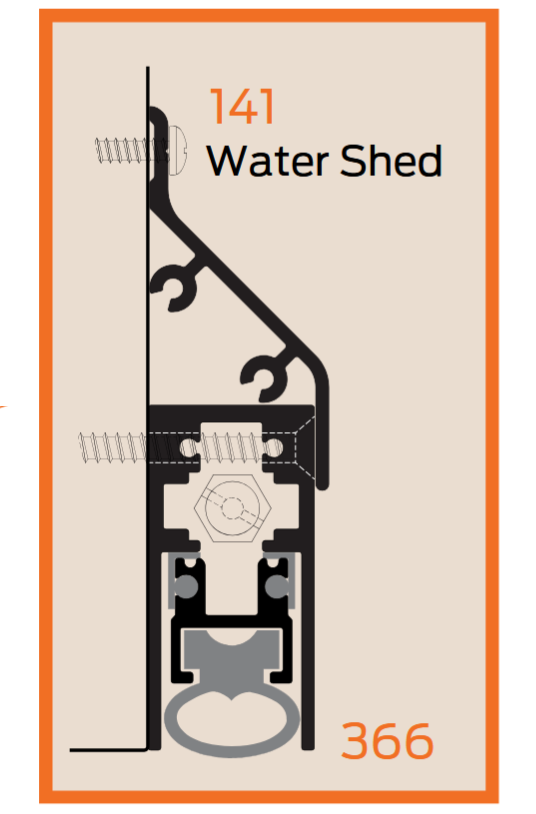

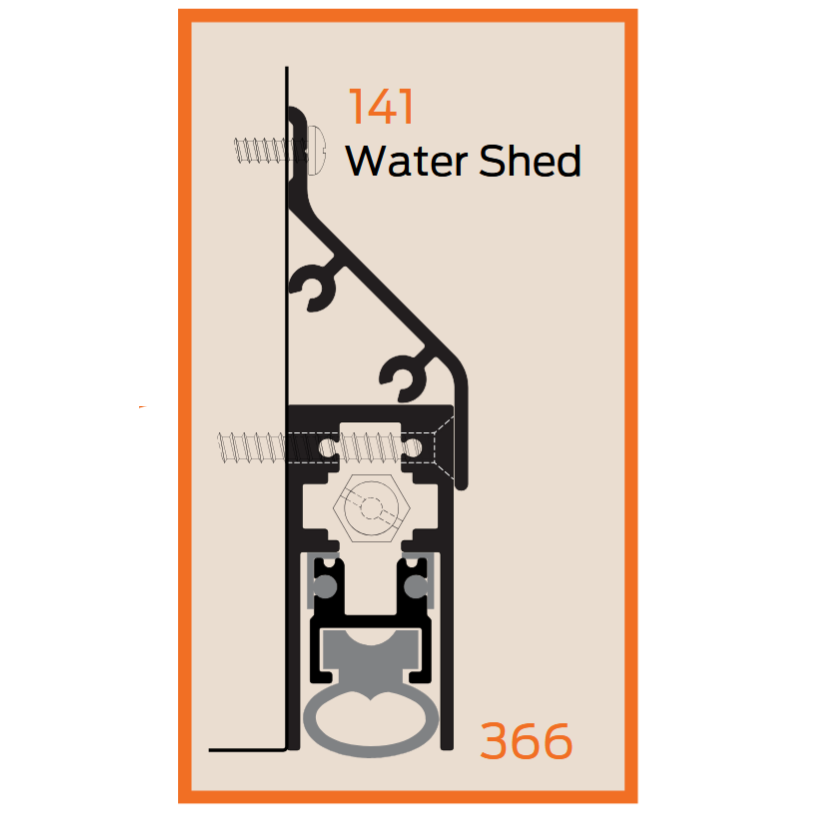

Initially, my answer was no – a surface mounted automatic door bottom does not comply with the accessibility requirements for manual doors to have a flush, smooth surface on the push side, measured 10 inches up from the floor. This requirement affects products like surface mounted vertical rod panic hardware with bottom rods and latches, full-height pulls mounted on the push side of the door, surface bolts, and kick-down stops, along with automatic door bottoms. The purpose is to provide a smooth surface that will not catch a cane, crutch, wheelchair footpad, etc., as someone is moving through the door opening. You can read more about the requirement in this Decoded article.

But what about this…there is an exception for glass doors with sloped bottom rails. Here’s what is required by both ICC A117.1 and the ADA standards:

Tempered glass doors without stiles and having a bottom rail or shoe with the top leading edge tapered at 60 degrees minimum from the horizontal shall not be required to meet the 10 inch (255 mm) bottom smooth surface height requirement.

Technically, this exception applies to tempered glass doors, but could an automatic door bottom with a sloped top be allowed by the AHJ as an equivalency? I’m going to add this to my wish list for consideration in the next round of changes to the standards, although that might be a while.

What do you think? WWYD?

You need to login or register to bookmark/favorite this content.

This comes up all the time, and Like you I’ve always said “No” and explained that they must use a mortised auto door bottom to meet the code. But what do you do when you have flush bolts or some other piece of mortised hardware trying to occupy the same space?…I think this is an AWESOME wish list item!!! 🙂

-MK

I’m not sure if this is apples to apples or apples to oranges. A standard tempered glass door is made with 3/8″ to 1/2″ thick glass (that’s a guess) and this exception specifically mentions tempered glass doors without stiles. As such, the only things bringing the door out to a standard 1-3/4″ thickness are the top and/or bottom rails. Having the top of the bottom rail tapered makes perfect sense since it prevents anything catching on the rail, especially if there is a slope to the floor.

Auto door bottoms, on the other hand, are applied to the face of a door that is already 1-3/4″ thick. Since I have no mobility issues (other than aging knees), I have no idea if this would be an issue. Would canes, walkers, wheelchairs catch the edge of that door bottom more often as a result of the added thickness? I don’t know. I’d be interested to find out. I guess it goes back to the thought processes mandating the beveled top and the limit of 1/16″ change of door plane.

IMO: yes, in principle this should be allowable, but the sloped piece needs to be 60deg. The various manufacturers will need to produce this piece for this purpose — either an aluminum extrusion or a piece of brake-formed sheet metal.

I had a hotel project where some conference room storefront doors swung out to a very busy boulevard and the noise was unacceptable; a simple blade type sweep on the pull side was insufficient. I asked for this automatic door bottom + deflection piece solution, but the local code officials rejected the solution due to lack of precedent and code support. You can guess how the hotel solved the problem…