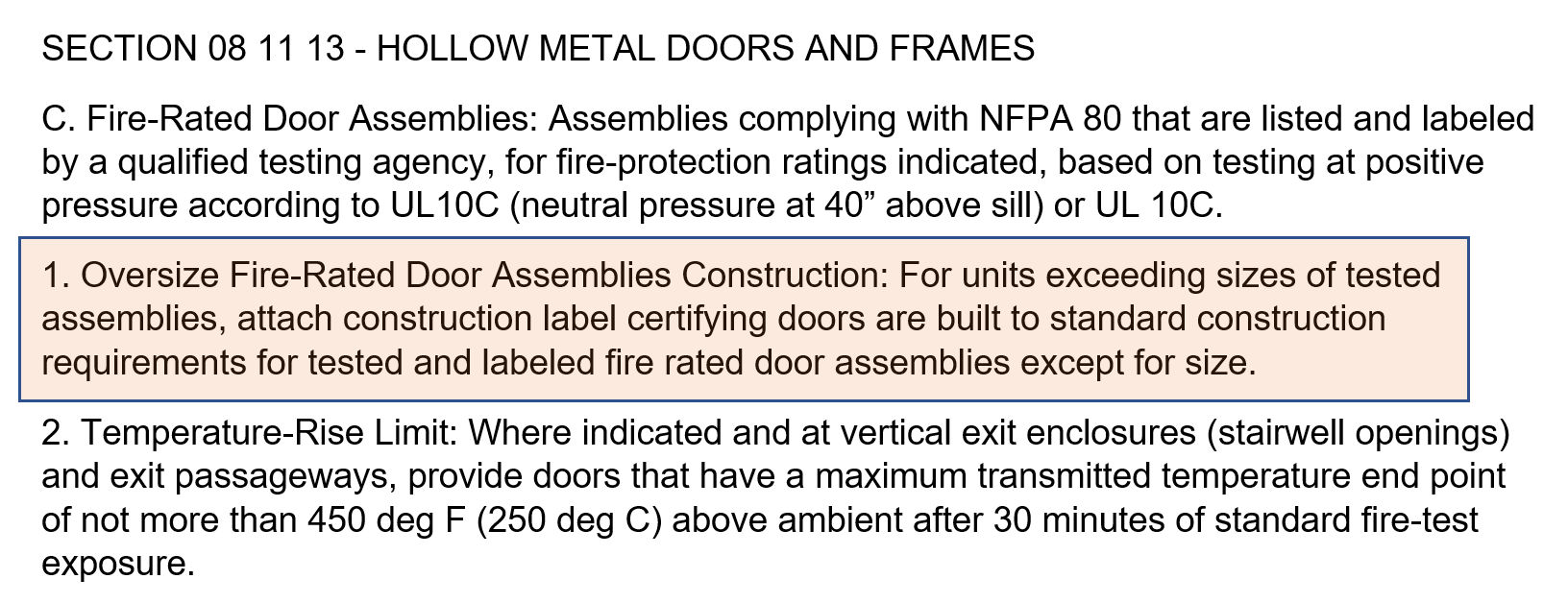

I have posted a couple of spec updates (1, 2), both related to one small portion of an actual project specification, and today’s post addresses the remaining paragraph in the example. I received questions from several readers about the paragraph on oversized fire door assemblies and the label requirements for those doors and frames:

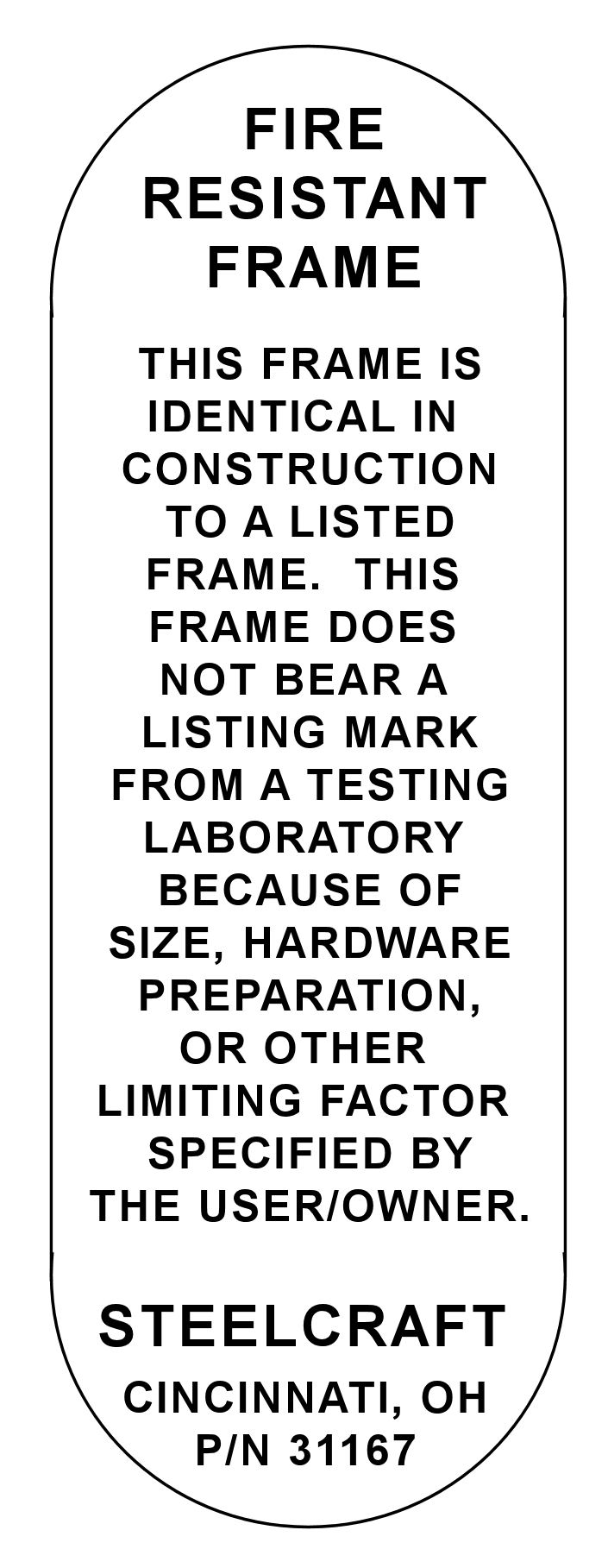

The maximum size of a fire door assembly is sometimes limited by the size of the test furnace – the NFPA 80 Handbook suggests that the maximum size tested is typically 4 feet x 10 feet. The specification paragraph requires oversized fire doors to have construction labels. A construction label is used when a fire door and/or frame is manufactured with the same materials, design, and construction as a labeled fire door assembly, but the configuration has not been subjected to a fire test. Generally, a fire door assembly with a construction label must be approved by the AHJ as an equivalency in order to be used.

The IBC refers to these labels in Section 716 – Opening Protectives, and allows oversized fire doors to have an “oversized fire door label” (AKA construction label) or a certificate of inspection:

The IBC refers to these labels in Section 716 – Opening Protectives, and allows oversized fire doors to have an “oversized fire door label” (AKA construction label) or a certificate of inspection:

716.2.9.2 Oversized doors. Oversized fire doors shall bear an oversized fire door label by an approved agency or shall be provided with a certificate of inspection furnished by an approved testing agency. Where a certificate of inspection is furnished by an approved testing agency, the certificate shall state that the door conforms to the requirements of design, materials and construction, but has not been subjected to the fire test.

NFPA 80 includes essentially the same language as the IBC, but also lists the information that must be on the label:

4.2.1.6 The label for oversized doors shall contain the following information:

4.2.1.6 The label for oversized doors shall contain the following information:

(1) The words “oversized fire door”

(2) The manufacturer’s company name or a code that can be traced back to the manufacturer

(3) The marking of a third-party certification agency

(4) The basis of a fire protection rating

The NFPA 80 Handbook includes additional information about oversized fire doors.

I think it’s acceptable to have a reference in the specification to oversized fire doors with construction labels, but I will say that in my 35 years in the industry I have seen VERY FEW fire door assemblies with construction labels. I could probably count my projects with oversized fire doors on one hand. I do remember a couple of fire-rated stage doors that were extra-tall to accommodate the movement of sets.

The AHJ approval is very important, because these oversized openings have not been tested to evaluate their performance in a fire. Someone should be making a conscious decision about whether fire door assemblies that have not been tested will provide the necessary level of protection.

So what do you think? Does the specification need any tweaks with regard to oversized fire doors and construction labels? Should the AHJ’s approval be mentioned? Is it worth including this paragraph in the spec considering how infrequently these doors are included in a project?

WWYD?

Please send me any spec sections where we can learn from analysis or suggestions for updating.

You need to login or register to bookmark/favorite this content.

I think it’s crazy to let the AHJ determine whether or not an oversized door is acceptable. They have less technical knowledge about the product than anyone else involved (manufacturer, distributor, etc.).

I don’t believe oversized doors should be allowed if they aren’t listed. I know that places restrictions for certain applications but how can anyone “approve” something that has not and cannot be tested? Why allow anyone to put that kind of liability on the AHJ?

I hear you and I don’t disagree, but AHJs are allowed to approve various things if they deem them equivalent. Some of the equivalencies they are asked to approve are much more complicated than an oversized fire door. I don’t know how they evaluate them.

– Lori

IMO all of the codes would better serve a whole variety of stakeholders who use the codes if about 90% of the code references to “AHJ approval” were simply removed and not allowed as an option. Having served on several of the codes in the past, I’ve witnessed firsthand many examples of poor and lazy code writing/editing that inserted “AHJ approval” in code language when it wasn’t needed but it either sounded good or was in a template someone was using.

Lawyers will use “and/or” in legal documents which are inherently incompatible words, yet they are too lazy to think it through and make a decision in terms of which word is correct. Code writing bodies/committees also need to think through what they are writing in terms of what the technical justification/rationale is for needing to allow AHJ approval. At the same time, those groups who oversee code writing bodies/committees need to provide clearer boundaries to these bodies/committees as to when AHJ approval may be permitted vs relying on the prescriptive language of code alone.

Realistically, the majority of these allowances really are not needed and many are never actually exercised. In my experience, most AJH’s strongly prefer to use the black and white of the code and like to stay away from gray areas of the code because all they do is create additional problems.

You make some good points, Larry!

– Lori

If I build an aircraft carrier out of the same materials and with the same method of construction as a dinghy, you’re going to have a bad time. While that is hyperbolic to the situation here, the underlying truth is that there are a number of structural factors for these doors that do NOT scale linearly, and heat deflection is one of them. The minimum depth/overlap between a door and a jamb, the strength of a compression anchor, the weld pattern of reinforcements: all are based on standard door size.

In my experience AHJ’s reach out directly to the manufacturer and ask them to write a letter stating that the product in question will do what is being asked. However, this is not a good practice as the manufacturer has interest in not replacing the product.

I do want to disclose that my experience with this was working with a Fire/Smoke Damper Manufacturer, in which case the project called for a larger damper than what was approved/listed by UL.

Thanks for sharing your insight, Daniel!

– Lori

What hardware can they use on the oversized doors? you would need the Hinges/Pivots, Locks, and Closers to be rated for this opening as well, as far as I know even the hardware that is rated and tested for large doors are only up to 4-0 x 10-0, not more.

Hi Leo –

If there is no hardware that is listed for the oversized door, I think all of the components should be considered together by the AHJ to determine whether the door with the construction label and the rest of the components are acceptable.

– Lori