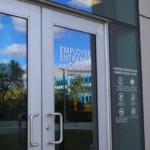

Nathan Langley from Phillips-Langley & Associates sent me this photo, and I received a similar question a couple of weeks ago. The application is in a building where the floors are out of level, and the fire door frames are installed with one jamb flush with the floor, leaving the other jamb with a gap between the bottom of the frame and the floor.

What needs to happen here in order to make the frame code-compliant? How much of a gap is too much? Is there a type of caulk that would be acceptable?

WWYD?

You need to login or register to bookmark/favorite this content.

Looks like some recent work done??

Is that a fairly new 1×6 or 1×12 to the right??

And was some trim removed under the door frame??

Maybe install fire retardant trim under the frame ??

Yes – the work is currently in progress.

– Lori

Once again appears the gap is through out the area. All walls??

Can they do a threshold if needed??

I don’t know if a threshold will solve the problem.

– Lori

The project is a historic renovation of a 100+ year old building with hardwood floors. The contractor says they installed the frames plumb, but due to changes in floor level, there’s this much difference from one side of the opening to the other (probably also to allow doors to swing). The gap under the new 1 x 6 trim will be covered with a shoe mold. Just wondering what a good answer would be here.

Possibly a spat if a UL rated one exists? Or, a labor intensive solution could be to undercut the other jamb to allow the pictured one to reach the floor. This would also require the door to be undercut as well but should maintain the rating i believe.

I have seen a 6″ brass finish “skirt” added to the bottom of the frame. It was when an assisted living facility, and I just assumed it was for appearance.

See below I have attach a fire-caulking data sheet(METACAULK® 835+) link, I’m also surprised to see a wooden floor.

http://www.rectorseal.com/web-media/data835.pdf

Lori: There are perhaps several scenarios, however most likely none of them UL approved. A two hour fire rated sealant material could be applied to the area below the frame, but it is susceptible to damage from foot traffic, cleaning etc. A welded extension to the frame could be utilized – labor intensive. The door itself will also be problematic unless cut to the floor slope – most likely – NOT. In order to meet clearnce requirements the door may require a rated drop bottom either morticed or surface applied to correct for the floor slope. A panic type threshold may also solve the problem, but must be used in conjunction with fire rated sealants or intumescent tapes. Just some thoughts.

David

I would use an epoxy grout, packed & tooled to match the games profile. Then paint with the frame.

Scribe-cut the opposite jamb leg so that the other leg sits flush to the floor, while the head remains plumb. If it is a fire labeled jamb, the cut would have to be done in a licensed shop. The door would have to be ordered with a large enough bottom rail to allow the door to be scribed in a similar fashion, and within compliance with the undercut range as stated in NFPA-80.

This is another case where a good carpenter would have scribed the jamb to match the slope of the existing floor. Then if needed undercut the door for proper gaps requirements.

Right. cut the other leg of the jamb, by the amount needed. If it is a steel door, properly sized to the frame it will fit and bring the under door gap into range.

IMHO, there probably is no 100% acceptable answer. For instance, if the hinge is on the “uphill” side, any door which meets the fire door requirements for clearance under the door will not open fully. So they have bigger issues than just the door jamb. However, one solution has been suggested which would come close. If you cut the “uphill” jamb down until the “downhill” side sits flush, then you cut the door bottom, too. But I would recommend cutting it high and level, and then installing an automatic fire-rated door bottom. I would use one with a brush, like Pemko 4301_NBL, that can be field trimmed to match the slope.

This is a challenging one for sure. ANSI A250.11, paragraph 3.4.1 states that shimming under the jamb legs is permitted but doesn’t specifically say how much is allowed. We may have to refer to the installation tolerances for clues. The elevated jamb leg will increase the 3/4″ maximum fire door undercut which doesn’t help, either. For that reason, I’m thinking a threshold will be required to keep the undercut within NFPA standards.

if it is a single door, the slope created (abt 1″ in 36″) is too uncomfortable even for pedestrian traffic, let alone the fire label requirement of the frame.

The floor is combustible on both sides of the door opening.

A raised noncombustible sill must be used.

Agreed?

I’m impressed the frame wasn’t installed with both jambs on the ground. I would have gotten a call from the door installer telling me the door was out of square and/or the strike didn’t align with the latch.

I agree with Daniel above…..grout and tool to the same profile as the frame then paint to match. Add a door bottom IF the undercut is greater than 3/4″ (we can’t assume the undercut is a problem without more data).

I agree with Brian, non-combustable sill is required.

If this building is 100 years old, are the walls truly fire rated. Just putting the frame in an unrated wall doesn’t make it a rated opening. The best solution is to scribe cut the opposing jamb, and lower the frame and have the door made or altered under appropriate label service to fit the now altered height. If a threshold is used, as some suggested, it would have to run under the high side of that frame jamb to the wall. The AHJ has the authority to allow for non-ADA compliance if they determine it needed for safety. Being a historic building egress can be modified if necessary. I would be surprised if the walls are truly rated and the fire barrier extends from below this level to the level below, since you have this much sag, and probably wood joists below.

Something I had not considered before was the testing of a fire-rated door bottom solution. Not surprisingly, this is addressed in another post here: http://idighardware.com/2017/06/qq-wwyd-excessive-clearance-on-fire-doors/