An architect recently sent me a question and I could use some suggestions from y’all. I know what I would do, but I’d like to hear other ideas.

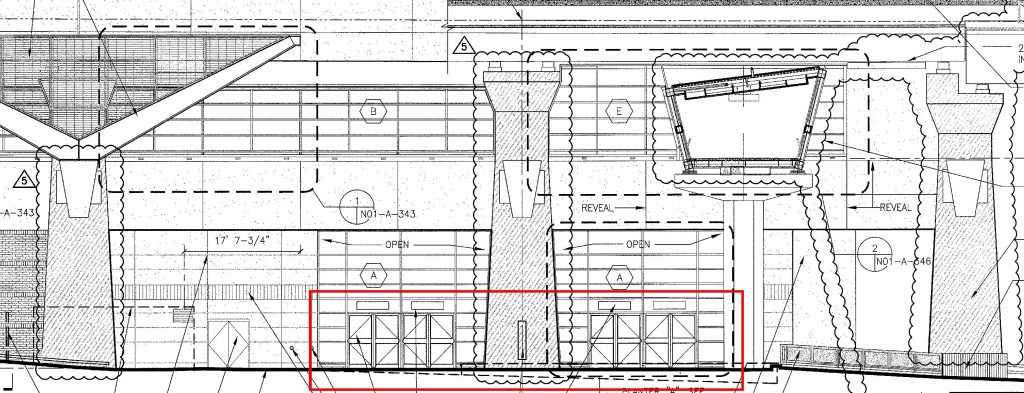

There are 4 pairs of doors involved, and each leaf is 4 feet wide x 9 feet 4 inches in height. They are part of a curtainwall system on the entrance to an urban transportation facility, so they are subject to high use and possibly some abuse. The doors are in the open position much of the time and there is no protection from the weather, so the existing panic hardware has begun to rust. There is a fair amount of wind which affects the closers, and the doors are currently hung on pivots.

WWYD to resolve these issues?

You need to login or register to bookmark/favorite this content.

Since the doors are open the majority of the time, and if locked, done by someone.

Just get rid of the panic hardware, and install a push/ pull bar or similar.

I think the occupant load is too high for a double-cylinder deadbolt, so if the doors have any sort of a lock it would have to be panic hardware.

– Lori

Remove them and install a different door type, probably an automatic sliding door. Actual use of the doors has proved that the design was not right for the client.

Replace them with Automatic Sliders

I’d call Andy Lindenberg, consultant extraordinaire, and get his input. Andy can figure out a good solution.

He is pretty extraordinary! 🙂

– Lori

Automatic Sliding Doors?

How about a simple cantilever awning? Drip cap on the door may also help (at least when the door is closed)

Not to do a shameless plug, but for doors exposed to the weather I prefer to specify the Detex weatherized exits. I’ll typically specify a clear powder coat for hardware in corrosive environments like indoor swimming pools.

I agree, sliders make sense in this location.

Remove the panic hardware and have it powder coated locally.

Those doors are just too large and heavy for any application, let alone a high use/abuse one, a classic example where the architect is more concerned with appearance than practicality. Continuous hinges might provide some relief of the load, but I agree with those who have suggested sliders. If those are VD 98/99 touchbars, I think they are aluminum and stainless steel and could not “rust” but the finish has definitely deteriorated.

Respectfully, nobody likes to see one of their colleagues thrown under the bus with a statement like “a classic example where the architect is more concerned with appearance than practicality,” unless you know the particulars of the project and can make this as a factual statement about this project.

I’m used to seeing many factors that affect design decisions, including initial costs. Sometimes we see initial costs drive decisions that do not always consider operational or long term functional costs, and sometimes the designers have their hands tied. Transit projects are notorious for having tight or constrained budgets. I’m not a cost control expert, but the sliders would probably be more expensive from a first cost standpoint compared to what was installed. We also don’t have enough information to know if those door sizes are needed to meet the exiting requirements.

From an energy standpoint, I think it also needs a vestibule in addition to the other comments that suggest sliding doors. All of these “retrofits” carry costs that have to be weighed against what kind of funding is available.

Maybe if they did some cleaning and maintence on them once a month or so they would be fine. They make stainless cleaners….. They look filthy. They would be fine.

How about using exits in US28 finish. Possibly doors with mid rails and Impact devices in US28.

I second the Detex weatherized devices. This setup will not void its warranty.

Von Duprin offers a stainless steel option. it is solid not plated.

Precision has a new “weatherized” 626W finish for its Apex 2000 exit devices. The material of the panic is chrome plated over brass and is intended for exterior use, natatoriums and water treatment facilities. It has passed testing to get certifications MIL-STD-810G 521.4 Icing/Freezing Rain and others. It resists rust, corrosion, and salt air over the full life of the product.

I would trade what I could for stainless steel or anodized aluminum and put weep holes in it to drain the water to help with the rust. If this, nor the sliding doors will work, then I suggest simply removing the hold-open feature on the doors. They already have cylinder dogging, they probably don’t NEED to be held open most of time. What did you actually end up doing?

Hi Krystina –

Thanks for these suggestions. The doors/hardware have not been changed yet.

– Lori

Replace the hardware and keep the doors closed! I don’t know if this is a vestibule or not but it’s certainly adding to their utilities to keep these doors open all the time.

Barring the common sense solution, automatic doors (sliding or otherwise) would be natural. Or perhaps a full-panel overhead door (not a sectional garage-door) with egress door panels built in would be possible. Would require a structural retrofit but it would work.

Some kind of awning or cover would be another alternative, but it would have to be pretty extensive if the doors are open most of the time.

Agreeing with Mr. Elder’s canopy. Also walls for wind protection.

years ago wasn’t a epoxy coated exit device available?

With regular maintenance, nothing rusts. Without regular maintenance even stainless steel will corrode. So the answer is replace the exit device with a same new one and clean/lubricate very regularly especially because of the location.