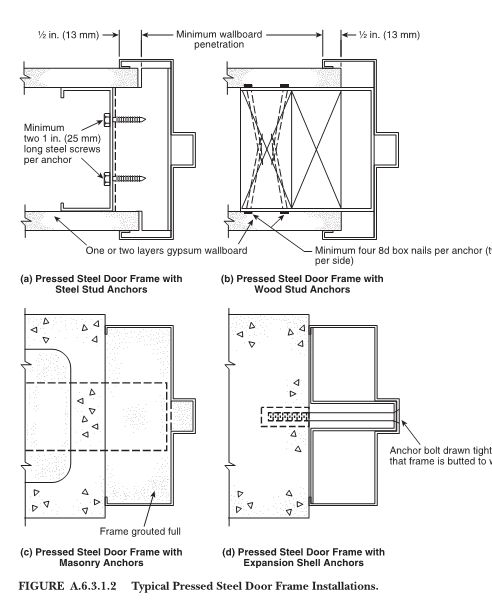

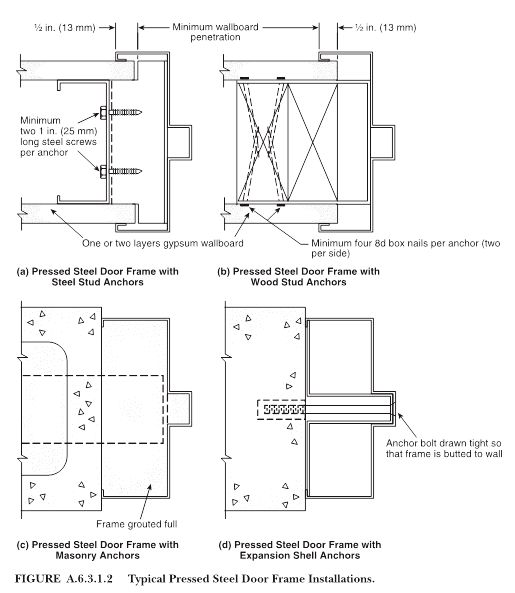

This question has come up a few times lately…many of us have been taught that sheetrock/drywall/wallboard has to penetrate at least 1/2 inch behind the returns on a fire-rated frame, but where is that stated?

I found the graphic below in NFPA 80 (all recent editions) with a line in Annex A stating that frames should be installed following the general guidelines shown in this figure. These details don’t cover all applications, and there are some additional details in NFPA 80 which show frames butted to existing walls, without wrapping the GWB. When in doubt, check with the frame manufacturer to see what is allowed by their listings (and refer to this post regarding existing wall anchors, and this one regarding mortar boxes).

I also asked UL what is stated in their requirements, because of an architectural detail in question, which showed one layer of GWB penetrating the frame on each side of the wall, and a second layer butted to the frame. The representative from UL said that having the frame wrap one layer on each side is acceptable, and the additional wall finish is not required to be wrapped by the frame.

As one of the commenters on this post mentioned, if the rating of the wall requires two layers of GWB on one or both sides, there should not be a gap between the end of the second layer of GWB and the return on the frame, as this leaves a space with less protection than what is required. I have worked on several projects where the architect wanted a “shadow gap” (AKA “shadow line”) around the frame. In some cases, a special frame profile with a couple of extra bends may be needed so the extra layer of GWB can butt up to the custom return while maintaining the aesthetic shadow gap.

Got a Quick Question? Leave it in the reply box!

Image: National Fire Protection Association – NFPA 80

You need to login or register to bookmark/favorite this content.

Lori,

I was informed (Don’t remember from whom) that when the Rating Requires 2 Layers per Side. The Frame does not have to Wrap the 2nd Layer. BUT, it must Butt up all the way to the Frame. By Leaving a Gap, there will be a Break in the Grade of the Rating.

That makes sense!

– Lori

Lori,

How about NFPA-80 Figure A.6.3.1.3(a) & Figure A.6.3.1.3(b) where the Frames are installed Butting up against Stud Walls and not Wrapping at all?

Those are existing walls, where it would not be feasible to wrap the GWB. I added a note to the post to clarify. Thanks!

– Lori

I dont see a real world scenario where a punch and dimple frame can be “screwed down till frame is tight against wall”. Rough opening and net overall frame can not be the same size.

True. I wrote a post about that topic a while ago: http://idighardware.com/2016/10/qq-fire-door-frames-with-existing-wall-anchors/. I will go back to the engineers and ask about existing openings with studs and sheetrock vs. the masonry openings that I referenced in the post.

– Lori

Where in NFPA-80 does it state that only one layer of drywall penetration is required regardless of the wall/door fire rating?

Hi Eric –

That is not specifically stated in NFPA 80.

– Lori

Do listings of rated frames which have been through the furnace show the minimum lap?

well we have to ask a question to the group as when a frame – Fire rated wall – to be replaced in a concrete block wall is required to have the concrete fill inside the frame or just bolted to the wall to meet current code? This is a question now as we been asked this a few times now this year with a few projects going on around the province (Canada) that have had to make changes to this and it good to bring up the GWB info to as reno sites are getting into this.

I was asked by a junior what the GBW stands for so think that if there is shorts used than give a quick info on the short form if there are those who don’t know.

Good idea Robert – I added the GWB info.

– Lori

ANSI/SDI A250.11-2012: 7.7.3 At wrap-around installations in fire rated walls, drywall shall extend at least 1⁄2˝ (12.7 mm) into frame throat. See Section 12 for frame installations in butted or existing stud walls.

How was the frame tested at the Lab for certification (U.L.,etc.)? That is the litmus test.

Did the testing lab strictly follow the mfg. spec’s?

About a month ago, I contacted NFPA directly to question how many layers of drywall are required to penetrate the frame throat. Here is the wording from my question “We understand when standard steel stud anchors are used on hollow metal frames, the drywall must project into the back of the frame throat by 1/2 in. In figure A.6.3.1.2 there is a statement “one or two layers gypsum…” By use of the word “or” does that mean the 2nd layer is optional or is it implying that 1-layer penetrates when it is a wall using a single layer of drywall and 2-layers must penetrate when it is a wall using a double layer of drywall?”

Their answer did not address my direct question & still left me wondering. Their answer was “The selection of the specific type of door and the specific type of fire resistance rated wall assembly will determine if one or two layers of gypsum wallboard are necessary.” I replied asking for further clarification and received no response. Disappointing.

We ended up getting a clarification from UL instead. (UL said only one layer needed to penetrate the frame throat). However, our AHJ is saying NFPA is being vague because it is up to the AHJ. Is there any chance you can get a more precise response from NFPA?

I doubt NFPA will get more specific, but if UL only requires 1 layer each side to penetrate the frame, I don’t know why the AHJ would require more.

– Lori

So how would you get 1/2″ penetration if you have a conduit cover box for an electric hinge? Would you just notch out gypsum wallboard and fire caulk that area?

Hi Jason –

Check out this post and see if it answers your question: https://idighardware.com/2018/12/more-on-gwb-penetration-fire-rated-frames/

If not, let me know!

– Lori

Hello.

Where can I find some documentation with codes about What is the minimum GWB penetration for a fire-rated frame? To show the General Contractor?

Thank you in advance