Sometimes a question crosses my desk that surprises me – it seems like after 6+ years of writing about doors and hardware every day I would have heard them all, but this was a first. I was asked to find out where in the codes it states that a removable mullion is acceptable to use on a fire door assembly; an AHJ had questioned the application because when the mullion is removed, the doors will no longer be positive-latching as required by the model codes and NFPA 80 – Standard for Fire Doors and Other Opening Protectives.

Sometimes a question crosses my desk that surprises me – it seems like after 6+ years of writing about doors and hardware every day I would have heard them all, but this was a first. I was asked to find out where in the codes it states that a removable mullion is acceptable to use on a fire door assembly; an AHJ had questioned the application because when the mullion is removed, the doors will no longer be positive-latching as required by the model codes and NFPA 80 – Standard for Fire Doors and Other Opening Protectives.

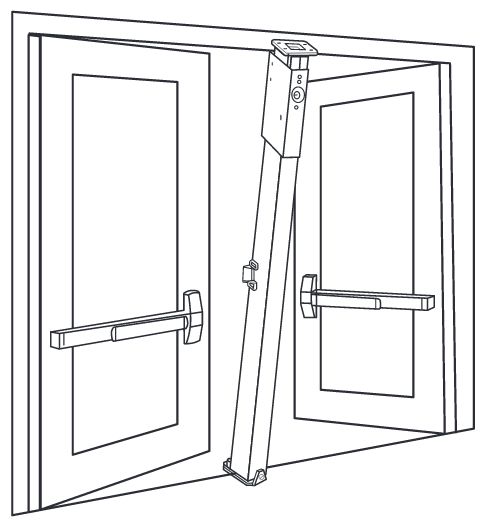

If you’re not familiar with a removable mullion that is made by manufacturers of panic hardware and fire exit hardware (like Von Duprin and Falcon), it is designed to sit behind the pair of doors, and the rim exit devices latch into it. When the full width of the pair is needed in order to move something large through the opening, the mullion can be removed – either by turning a key in a cylinder or by removing screws. There is an article and video about removable mullions here.

Although there are many removable mullions which have been tested and listed for use on a fire door assembly (not all removable mullions are certified for this purpose), I have not found anything in the codes or standards that specifically addresses them. Removable mullions are quite common, so a code requirement related to their use on a fire door assembly must have slipped through the cracks.

NFPA 80 has a definition for “mullion” but no specific reference to removable mullions:

3.3.86 Mullion. A fixed or removable vertical member set in a double door opening that allows both leaves to be active or set between a door and a side light or a separate, framed, glazed area.

One paragraph in NFPA 80 can help us to understand the intent of the standard with regard to temporary conditions, but is relative to removable transom panels, not removable mullions:

6.3.4.2 Removable transom panels shall be permitted to allow for movement of materials or equipment through the opening.

I’ve added this to my code development wish list, but it won’t be addressed until the 2019 edition of NFPA 80. In the meantime, WWYD to explain to an AHJ that this is an acceptable application?

You need to login or register to bookmark/favorite this content.

It needs to be noted that there are Fire Rated Removable Mullions and “Regular” Removable Mullions. They are different. As pointed out the Rated units have been tested. The attachment at the base is taller. A floor buffer will often not fit over the rated unit’s base. And (obviously) the mullions need to be replace after they are removed. Wasn’t there a wall bracket once available to store the removed mullion? Allowed the mullion to be stored near where it belonged.

Thanks! I made a slight edit to the post to make sure it was clear that not all removable mullions are listed for use on a fire door assembly. There is a wall bracket available, but it is not widely used.

For this AHJ, it seems that the problem is not whether the mullion is rated but what is the guaranty that whoever removes it will remember to put it back as soon as possible. Imagine it’s late Friday afternoon and you stayed late to get that big thing through the doors and now you just want to get out of there. If it’s a non locking pair, you might not get too worked up about it when you’re sipping your Lagavulin 16 and realize you left the mullion in the corridor.

As one as stated it has to be tested as a complete assembly.

So once installed it has to be maintained.

Just like any other door and pictures you post. you cannot predict what the end user will do

I would explain to the AHJ that it is being supplied per code and that if the end user does not replace it properly it would no different than someone adding a kick down door holder on a labeled door.

It should be noted that when using a mullion, removable on not, in a fire rated opening and installing a pair of 99F exit devices, the 299F strikes supplied with the devices need to be exchanged for 499F strikes to be compliant. The 499F has an interlocking piece that is attached to the door to act as a stablilzer when the opening is subjected to high heat. As to the original question, it would be nice to see some clarification on the subject. Jack O. said it correctly, the mullion needs to be reinstalled promptly. Lori, keep it up. The only way we can remember all of this stuff is to beat it into us by seeing it repeatedly.

Original question of how would I explain this to the AHJ. 1. The removable mullion is available tested and rated for fire openings. 2. The exit devices have special strikes available and tested for this installation. 3. Why would this stuff be available and why would the manufacturer incur the cost of testing and rating if it was not compliant? Answer . . . People smarter than us have already thought of this and planned for it, please sign off on it.

Not putting a removable million back in place is not unlike disconnecting closer arms, using door wedges, taping latchbolts in the retracted position or filling latch bolt holes in strikes, the opening must be maintained in a manner that meets code requirements. That is why inspections of fire-rated openings is so important.

During a fire inspection I found a center mullion removed in a school in my jurisdiction. They had brought a lift through the doors to the gym to replace lights mounted on the ceiling. I told them to replace it now that the work was complete and I noted it for my re-inspection. Turns out that somebody must of threw it out accidentally and they had to order a new one. It took several conversations with different school officials to explain why it is needed.

Interesting…I wonder how we could increase awareness. Maybe a permanent sticker on the mullion?

If we apply stickers to mullions we would have to apply them to everything. Closer arms, strikes, latches, kick-down holders, etc., etc., etc.

I can see it now. There’s a sticker warning that the mullion has to be reinstalled immediately but there’s not one on the closer arm. The mullion is removed and the closer arm is disconnected. Something terrible happens and the excuse is that the mullion had a sticker but the closer arm didn’t. You know it would happen. LOL

David, where is this located in the code and what prompts the use of mullions in double doors, and or double fire doors? I’m looking and I think I just keep missing it, can you point me in the right direction?

In case David doesn’t see your reply on his comment…mullions are not required by code – they are usually used because a removable mullion with rim panic hardware is more secure and easier to maintain than vertical rod panic hardware. There’s nothing in the codes or standards that says a pair of fire doors has to have a mullion (the doors could have vertical rod fire exit hardware or auto flush bolts), but once an application with a mullion is chosen, the doors won’t latch without the mullion. That is a code problem on fire doors, and a security problem on all doors. I hope that makes sense. There is a video here that shows the mullion: https://idighardware.com/2012/02/mullions-whats-not-to-love/.

– Lori

These are all wonderful comments, i really enjoy this forum and am grateful for Lori’s Leadership, has it only been 6+ years?? Lori, i cannot imagine the number of new folks who benefit from your blog, i’ve been at it a while and between your comments and folks who write in, well, let’s say i learn something with every post.

I think the issue raised by the Code Official is valid, but only in a case where compliance is less than understood. The removable mullion is quick and easy to remove, the alternative is slow and may not get reinstalled correctly.

Every fire door is subject to periods of non-compliance, the fire door that gets a broken window gets repaired, but while the window is broken, we know that the repair could be a week to get done, and the door would go some time with no window at all during repair – half a day – who knows,

i really liked response from Mr. Adkisson and the respondent known as Rich.

Best wishes,

kev

Here at our site, we have mullions on card access doors. We always have them labeled with our own tag that states that we need to be called if it needs to be removed. If the contractor or someone in the building removes it, they are billed for it. That seems to keep them calling us so we can maintain them.

I like that idea! You know what they say…”Money talks…”

ok we have a great question for the group

ok so we have one case were there are 99EO double doors with a removable mullion and yes if gone than it does not meet code.

here is the question

if with the same set of double doors and removable mullion and there are 9957 used and the doors are set up that there is a 1/8″ gap as required and the mullion is gone – ___ does it still meet code as fire doors with 9927 do and no mullion — so if there is a set up with 9957 with a removable mullion and it goes missing as they do and it still close and latch in this mode will it meet code???

Oh, that IS a good question. Seems like it would still be compliant, just not as forced-entry resistant. It has the same top and bottom latches as the 9927.

One other thing: when the mullion is removed, the bottom mounting bracket is still fastened to the floor — it’s a formidable trip hazard and point of liability.

Would it be practical to have a mullion hinged to the ceiling with an alarm-connected magnetic hold-up and a noise-making speed check to avoid clonking anyone on the head? In case of a fire alarm, the mullion would fall into place; since it would be located on the push side of the door, so a coordinator should not be required.

Hmmm…could be interesting but I don’t know if anyone would pay the price. Good idea, though!

My granddaughter suffered and incident relating to a mullion. She was running full tilt a school, looked back and turned in time to get the mullion in her face. She is 5 years old. While fire is the reason for many building safety items, there are other reasons to maybe pick something else other than a central mullion in a means of egress doorway. To me there is a similar issue when fire codes are the main consideration of escaping a building. Situations such as an armed shooter should also be kept in mind along with fire.

Sorry to hear about your granddaughter!

– Lori

What are the parameters of the fire test for removable hardware mullions (mullion behind the doors)?

Is the a requirement of maximum gap between the doors (ie: 1/8″) or can the gap be larger due to the fact that a removable hardware mullion has a 2″ face meeting the door faces. In other words can the gap be 1/2″ or 1/4″ or 3/8″, etc.? Do the manufacturers have this criteria in their listing?

On the assisted living project I am working on the AHJ is citing NFPA 18.2.2.5.7 & 18.3.7.8*.

Plain as day it says no mullions. I haven’t had time to dig further into it though to see if my doors are classified as noted.

I just wanted to post those sections in case it helps others and for future reference.

I believe it is not the Mullion itself that is the non-compliancy issue. It is not even the removal of the Mullion, but rather the subsequent lack of re-installing the Mullion that posses the non-compliancy issue. This is much like the manual flush bolts installed on a pair of doors that is allowed for in Chap 6.4.4.5.1* of NFPA 80 (2013 Edition) as long as it is acceptable to the AHJ, and provided that they do not pose a hazard to safety to life. Annex A.6.4.4.5.1 states that this provision limits their use to rooms not normally occupied by humans (eg., transformer vaults and storage rooms). It is presumed that the one who removed the Mullion (or unlocked the manual Flush Bolts) would have the knowledge to re-install it when finished with the task that created the reason for the removal or unlocking in the first place. That being said…we are all human beings and subject to shortcomings.