I received a question the other day about grouting hollow metal frames. Is it recommended? Necessary? I’ll admit that I don’t know a lot about grout, but I do know people who do – and some of you are reading this right now!

I checked out what the Steel Door Institute (SDI) had to say, and this article talks about the risks associated with grouting frames. For frames in drywall construction, grouting the frame is not recommended because the moisture will either affect the drywall or the frame. If grouted frames are desired for masonry construction, the grout should be troweled, not pumped in as a thin slurry which has excess water that could cause the frames to rust. Check out the SDI article for links to additional resources on grouted frames.

The Hollow Metal Manufacturers Association (HMMA) has a publication on grouting hollow metal frames, which suggests that grout may improve frame durability, sound deadening, and anchorage strength, and recommends grouted frames for detention applications. The publication also warns against grout that is improperly used, describes the potential negative effects, and includes recommended practices for using grout in hollow metal frames.

The Steelcraft Technical Data Manual includes the following cautionary information with regard to grout:

Installation Caution Notice – Grouted Frames:

When temperature conditions necessitate an additive to be used in the mortar to prevent freezing, the contractor installing the frames must coat the inside of frames in the field with a corrosion resistant coating per SDI 105.

When frames are to be grouted full, silencers must be field installed prior to grouting.

Steel frames, including fire rated frames, do not require grouting. Grouting is not recommended for frames in drywall.

Steelcraft also includes information on a recommended coating for use with grouted frames. I have seen coatings specified before – bituminous coatings and other types, to help prevent corrosion from within the frame. Another related issue is the type/treatment of the steel – galvanized or galvannealed, and to what level.

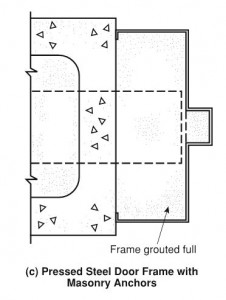

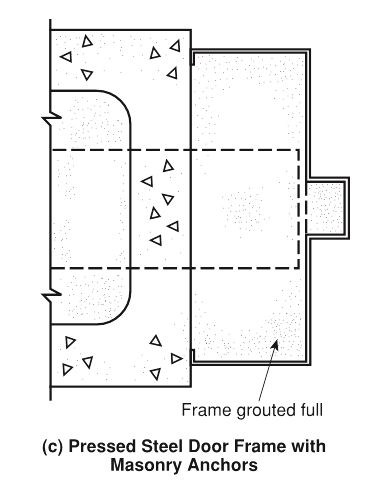

I have worked with architects who specified grout for fire-rated frames, but as far as I know this is not typically required by the listing procedures. NFPA 80 – Standard for Fire Doors and Other Opening Protectives does not state that grout is required, although a figure included in Annex A may be contributing to the belief that it is. Figure A.4.6.3.1(g) shows “Typical Pressed Steel Door Frame Installations”, and one of the frame details, the one illustrating a hollow metal frame installed in a masonry wall, is annotated “Frame Grouted Full”. Another issue to add to my code development wish list.

I have worked with architects who specified grout for fire-rated frames, but as far as I know this is not typically required by the listing procedures. NFPA 80 – Standard for Fire Doors and Other Opening Protectives does not state that grout is required, although a figure included in Annex A may be contributing to the belief that it is. Figure A.4.6.3.1(g) shows “Typical Pressed Steel Door Frame Installations”, and one of the frame details, the one illustrating a hollow metal frame installed in a masonry wall, is annotated “Frame Grouted Full”. Another issue to add to my code development wish list.

I would love your help with more information on these issues…

-

Is grouting still prevalent? In what types of construction and for what reasons?

-

Are specifications calling for hand-troweled grout, or is grout typically being pumped in?

-

What is the preferred type of steel for exterior frames?

-

Is a coating required for grout-filled frames?

-

Any other grout-related issues you’d like to discuss?

-

If you have any illustrative photos of grout-gone-wrong, you know what to do!

Here’s a video from Steelcraft which illustrates the recommended practices for installing a hollow metal frame in a masonry wall:

Graphic: NFPA 80 – 2013

You need to login or register to bookmark/favorite this content.

In the retro world I cant recall ever being asked to grout or using it. On CMU’s its normally just FSA’s field applied.

The coating does sound like a good additional process if you are grouting…. I’m thinking maybe Flex Seal since it does a good job on row boats/screen doors.

The only place I would occasionally grout would be under thresholds on rear kitchen entrance doors.

When in private practice, I used grouted frames in high impact and high vandal prone areas (high schools in particular). Grout and steel do not go well together. However, as indicated in the Steelcraft note, a good bituminous coating on all surfaces to receive grout will provide significant protection. In drywall, we would attach the frame to a solid stud runner to contain the grout – the runner also protected with bituminous coating. With this treatment, I never experienced either short- or long-term moisture or rust problems associated with the grouting.

I won’t quote the entire passage and verse but check out ANSI/SDI A250.8, paragraph 4.2.2.

I read from prepared text (and it really is in caps): “GROUTING SHALL NOT BE USED FOR FRAMES INSTALLED IN DRYWALL WALLS.”

HMMMM.

We typically call out for all frames to be filled with mineral wool insulation.

This helps with sound and gets away from issues with grout.

Another day that I learned something from your blog. Good stuff.

I just watched this great video from Steelcraft on installing masonry frames, and for the first time I saw the actual grouting process while the frame was being installed. https://www.youtube.com/watch?v=3XzJpF9dXJw Up to this point I wasn’t sure how it worked. When we do frames for existing openings, we are sometimes asked for grout access holes at the top of each jamb so that they can be filled after installation with grout. This can be problematic if not done carefully because if they are overfilled, they they can cause the frame to be out of square.

Thanks Rachel – I just added the video to the post.

If grout is used it must not have gypsum in it. The gypsum continues to attract moisture from humidity for years which accumulates in the frames eventually rusting thru.

Frames are installed differently in Asia. The most common technique is for the contractor to build the opening without a frame. The frame is installed quite late in the building process. Frames come from the manufacturer with a plate welded across the frame backbends at about the same locations where you would install the wire or strap anchors. This plate has a hole in the center; it looks like a retrofit frame but there are no holes in the soffit. When the time comes to install doors and frames, the installation team drills holes in the wall at the location of the holes in the mounting plates attached to the frame. They install lag bolts in the wall, hook the frame over the bolts, and attach the frame to the bolts using an arc welder (SMAW). One person holds the frame in position, and the other welds. They use a steel tape to get the width correct at the base, and a bubble level on the frame. As laser level prices drop, it seems like there is one in every room and those make it much easier. After the frame is welded to the anchors, a second team grouts it using a stiff grout. Frame heads are rarely grouted.

There are pros and cons to this method. The good part is that the frame doesn’t get beat up during construction, and other trades have an easier time getting through the wider opening. We have not had a problem with frames rusting from the inside, but we have had problem with broken welds between the anchor and back plate. The biggest problem we have is getting the frame plumb, level and square. The laser level helps. On some projects we have a team with a laser level inspect every installation after welding and before grouting. The other problem with this method is that the frame and/or wall opening aren’t always the right size. With this method you discover the problem later and it’s harder to fix.

I’ll try to take some videos and send them to you.

Thanks Lloyd!

Frames are installed differently in Asia. The most common technique is for the contractor to build the opening without a frame. The frame is installed quite late in the building process. Frames come from the manufacturer with a plate welded across the frame backbends at about the same locations where you would install the wire or strap anchors. This plate has a hole in the center; it looks like a retrofit frame but there are no holes in the soffit. When the time comes to install doors and frames, the installation team drills holes in the wall at the location of the holes in the mounting plates attached to the frame. They install lag bolts in the wall, hook the frame over the bolts, and attach the frame to the bolts using an arc welder (SMAW). One person holds the frame in position, and the other welds. They use a steel tape to get the width correct at the base, and a bubble level on the frame. As laser level prices drop, it seems like there is one in every room and those make it much easier. After the frame is welded to the anchors, a second team grouts it using a stiff grout. Frame heads are rarely grouted.

There are pros and cons to this method. The good part is that the frame doesn’t get beat up during construction, and other trades have an easier time getting through the wider opening. We have not had a problem with frames rusting from the inside, but we have had problem with broken welds between the anchor and back plate. The biggest problem we have is getting the frame plumb, level and square. The laser level helps. On some projects we have a team with a laser level inspect every installation after welding and before grouting. The other problem with this method is that the frame and/or wall opening aren’t always the right size. With this method you discover the problem later and it’s harder to fix.

I’ll try to take some videos and send them to you.

At the point when in private practice, I utilized grouted outlines as a part of high effect and high vandal inclined territories (secondary schools specifically). Grout and steel don’t go well together. Be that as it may, as demonstrated in the Steelcraft note, a great bituminous covering on all surfaces to get grout will give huge insurance. In drywall, we would append the edge to a strong stud runner to contain the grout – the runner likewise ensured with bituminous covering. With this treatment, I never experienced either short-or long haul dampness or rust issues connected with the grouting. Thanks!

Thanks for sharing your insight Jaime!

– Lori

Great video, thanks for posting this!

Here is a question not exactly about filling frames with grout, but instead with insulation. I have seen specs which call for filling exterior door frames with spray foam insulation to increase thermal properties. Is this an accepted or even desirable or necessary practice?

A few comments I would like to make.

Epoxy primer protects the steel from rusting.

I liked the ideas about bitumous, flex seal how ever if the frame is fire rated make sure the sealer will not impede the rating.

In relation to core filling, be mindful of heat, fire super heats the steel and the heat transfers from one side of the opening to the other. Whilst rock wool ticks all the boxes over concrete or gypsum it works to well, it does not pull the heat from the steel, ironically bad insulation like gyprock, concrete act as a better heat sinc. It’s crazy logic. I can’t find information on insulating heat sinc s it’s an oxymoron.