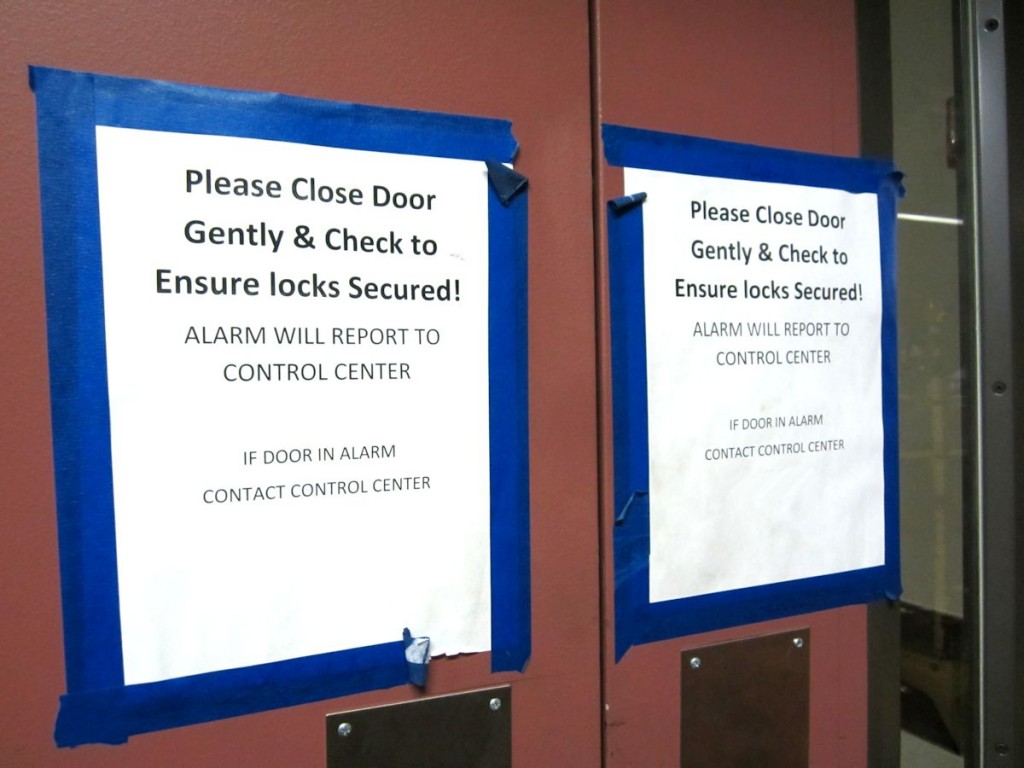

I recently visited a facility where security is their top priority. Many of the doors are set to sound an alarm if they are left open for more than 6 seconds. This presents a challenge when carts are being moved through the opening, because the doors need to stay open long enough for the carts, but need to close before the 6-second mark. There are 10,000 employees on-site during a typical day, and leaving a door unsecure / not locked or latched can result in termination of their jobs. Many of the doors are fire doors, which adds some extra complexity to the issue. Almost all of the doors have access-control.

I stood at several of these openings and watched the employees attempt to make the doors function as needed. A guy on a cart came along and jumped off the cart, flung the door open, jumped back on the cart and drove it through, hitting the door with the cart as he went. Then he jumped off the cart and forced the door closed.

Have you ever dealt with a similar situation? What would you do?

Update: To answer a few of the questions that were left in the comments…the doors in these photos have a prox reader, keypad, and biometric reader. The time limit on having the door open (6 seconds or 15 seconds for most of these openings) is not something that is within the facilities department’s control. There are some cameras in the facility, but they do not monitor each door with cameras because it would be cost-prohibitive to monitor all of them.

You need to login or register to bookmark/favorite this content.

Assuming this door is controlled by a card reader. If the software for the system allows, I would program specific card holders who regularly use carts, with a longer held open time. I would install “Anti-tailgate” photo beams to detect direction of travel and confirm only one person at a time has gone through. This provides extra security while the door is open, so closing quickly is less of an issue. If there is no card reader, the photo beams could still perform the same function with some internal or external logic.

Great ideas – thanks Scott!

how about high speed fabric doors, they come vertical and horizontal, and are used for a variety of reasons HVAC considerations, cleanrooms.

if they need fires separation doors they could put a rated roll down door on the other side

That’s an interesting opening for sure. Looks like the doors used to swing the other way. That would explain the CVR strikes in the floor.

What kind of credential are the employees using to get through the opening?

Yes, the swing was changed on these (good eye!). The employees have badges…I didn’t investigate too far because they would have had to kill me. 🙂

With the above said I would add NEW Closers to these doors.

look at the old junk on the doors.

Of course the NEW LCN 4040 series would do the job just fine.

That is assuming they really do want the doors to close by themselves.

Sounds like someone has security issues

If someone cannot watch the doors for awhile and see what the average time it takes people or carts to go thorough, and then set the time for that average, they have bigger issues

They already know who went through the door and I imagine they have a few cameras

Sounds like they are making more wasted work for the security force

Auto operators and adjust the door prop alarm to time with the operators.

I suggested auto operators when I saw the cart go through, but the low energy operators don’t open and close the door fast enough. They could go to full powered operators with mats and rails in some locations but not most.

Even low energy operators would probably cycle faster than the act of dismounting the vehicle and pushing the doors open, driving through, dismounting again to secure doors and remounting the vehicle ? Not sure what the credential is to activate but we put long range read credentials on vehicles so that the door/gate operators will start the opening process while the vehicle is still a fair distance from the opening. Anti-passback/tailgating issues can be handled through the software.

We talked about actuating the low energy operators from farther away but they had security concerns as well as concerns about investing so much $$ in a door which would probably get beat up quickly. I told them they need employee training and consequences for door abuse.

Years ago I worked on a project were we used the rapid roll fabric doors for this situation. The workers were on forklifts with parts for jet engines. We calculated the speed of the forklift and placed the up/down button on a pedistal the required distance from door. The forklift drivers didn’t need to slow down unless they missed hitting the button. And of course they still tried to hit the door. Go figure? Needless to say the fabric doors were not fire rated – see Curtis above. Now prox readers could be used to activate.

Are the fire rated doors required??

What is the setup on those, do they have positive latching??

These particular doors don’t have positive latching – just mag-locks, but many of the doors are rated and do have the required latching hardware.

I bet that propping the doors open is the real issue and not the 6 seconds. As long as the door is in active use it wouldn’t violate the “required” fire door issue. Install a camera and when the 6 seconds is violated, sound a “trouble” alarm for security to view and see if its legit or not.