I was reading an article about blogging in Inc. the other day, and one paragraph really resonated with me:

“The thing most people don’t understand is that the difference between a blog post and a magazine article is the difference between conversation and presentation,” notes Strauss. “If I were giving a presentation on a stage behind a podium, the expectation is that I’m going deliver a fully developed idea with everything tied up in a bow and a potential Q&A at the end. In blogging, it’s important to blog about a particular topic without being complete. If it’s conversational as a blog is supposed to be, you get a chance to say one thing or one idea, and then it’s your customers’ turn to talk or respond.“

When I first started this blog, I always tried to have a completely formulated answer to the question (it’s a personality flaw). But over time I realized that I can just start the conversation and other people will chime in. I received a question last night from a hardware distributor that I couldn’t completely answer. The conversation went something like this:

Ken: “Do you have a preference, or is one better than the other, when it comes to swing clear hinges and beveled versus square edge hinge stiles?”

Me: “I can’t think why it would matter as long as the hinge is of the proper type to match the door edge. I checked the Ives catalog and their standard is square edge, with an option for beveled. I think the hinges must accommodate the edge so that the door sits in the same position when it’s open, so I guess we have to consider what happens when the door is closed. I like beveled-edge doors (regardless of the hinge type) because I think they bind less. So basically, beveled edge doors are my preference, swing-clear hinges appear to be sold for square-edged doors standard with the availability of beveled. I think you could argue both sides but I don’t think there’s a clear winner.”

Ken: “I agree, beveled edges on the hinge side do bind less. However, on full-mortise continuous hinges I like to use a square hinge edge since a beveled hinge edge works against you on clearance. Since the pivot point of the hinge projects out from the face of the door and frame, the hinge actually opens a little bit to match the angle of the bevel, this causes the door to move which increases the gap at the hinge side and closes the gap at the lock side. This has a tendency to increase the amount of clearance needed for this type of hinge.”

Me: “Huh.”

So, Dear Readers, I know you have opinions on this matter…in fact, I can almost predict who will be the first responders. Square edge or beveled edge doors, and WHY?

Thank you to Ken Adkisson of Isenhour Door for getting this conversation started.

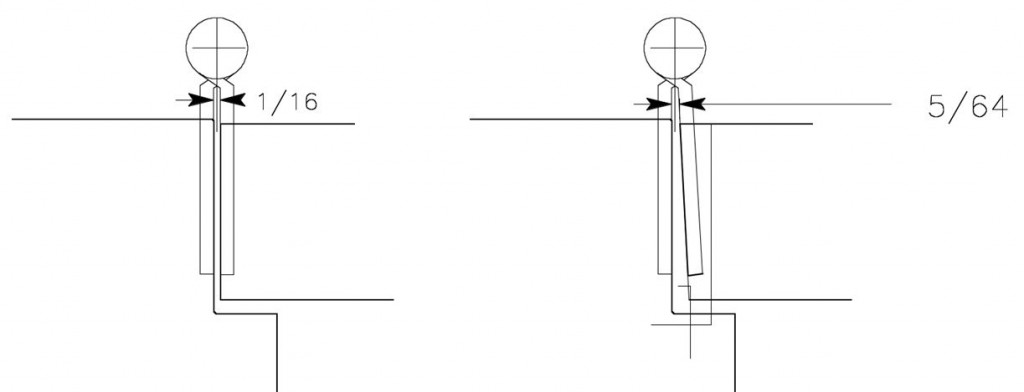

UPDATE: Thank you to everyone who chimed in on this topic. My friend and fellow code-head Zeke Wolfskehl sent me this drawing which illustrates the effect of the door edge on the clearance:

You need to login or register to bookmark/favorite this content.

‘Cause the door you’re putting them on has the one, but not the other.

OK, so here is the thing about being a custom door manufacturer. We match the hinge edge to what is required for the particular swing clear or continuous hinge being used. Some just don’t work well with beveled edges. And yes, you have to have different clearances for the different door edges. But, then, we can manufacture the lock edge still with a beveled edge which is our preferred lock edge. So for us, it can be mix and match, but I think with most manufacturers it has to be the same on both edges of the door. I would love to hear from other door manufacturers on their thoughts on this.

On wood doors, we use a beveled edge and a standard butt hinge for square edge because it does move the door out a little towards the latch side. We undersize single doors by 1/4″ in width because 3/16 doesn’t seem to be enough when a door swells in hot humid air. A standard hinge only has 1/16 clearance when closed and very rarely will you find an installer that will shim the hinge to a 1/8″ clearance. This arrangement has given us the least trouble over the years. It leaves plenty of shimming possibilities. Did you know that you can actually shim a door away from the latch side? By putting a half-shim along the stop side of the shim and tightening the knuckle side screws first, it moves the pivot point of the knuckle away from the latch side.

Ceco & Curries standard handed HM doors have a square hinge edge and a beveled lock edge.

You have to specify and pay extra for a beveled hinge edge door.

They also will not make the beveled hinge edge door on their quick ship programs, only standard production lead times.

I am not saying that 1 is better than the other, although with widely used compression smoke gasketing, the beveled edge door will close easier at installation and will not have to wait for the gasketing to “seat” itself the way it does with a square edge door. This will force the installer to adjust the closer a little to get the lock to positively latch. Once the gasketing has conformed itself or “seated” itself to the opening, you can adjust the closer so that the door is not slamming itself shut to try and latch the hardware.

If the hinge side is square then the lock side is square

making the door reversible by flipping the hinge and handing shim.

If the hinge side is beveled then the lock side is beveled and the door is handed & not reversible

Amweld/Steelcraft 6/8 x 161 hardware location the door can be beveled and reversible by flipping the door. All Amweld/Steelcraft any height door hinge location measure the same from top to bottom as well as bottom to top. Its the locking hardware location that hand a beveled Amweld/Steelcraft HM Door.

From the installation point of view; rarely is the door installer the guy who sets the frame. The frame is usually set by the Drywall / framer / Mason. These guys very rarely have a clue how to set a frame. As long as the bubble is in between the lines of the level they think it’s good, let alone even knowing what cross site means, Plumb Bob is guy that works for another company. ANSI 250.11 says you get 1/16th of an inch overall, so I will stop there get off my soap box and move on to “Square or Beveled”. Definitely / always beveled both sides; this is not the Age of the Craftsman; its blow and go without any thought to quality, just get the job done. Sad but true. The 1/8” in 2” bevel makes all the difference in swinging a door in frame these days while trying to maintain the integrity of the gaps between the frame and door edge. The code says a 1/8” on a wood door unless the frame is set perfect this is impossible to achieve. This leads in to part two; swing clear hinges. The pivot point of the swing clear hinge is very difficult to shim away from the strike jamb. Bob says you can and I agree but nowhere near the same amount as a regular butt hinge and if you have the bevel on the door you can achieve a greater distance. You can push it toward the strike all you want. On swing clear hinges I would follow my previous comment “always” beveled, I like being consistent. Daniel makes a good point of the installer adjusting the closer to compensate for gasketing but he also does it for a poorly set frame and then again I am back on the soap box. Rachel makes the point of what hinge are you putting on that door which is great because she is willing to ask the questions where others may not. I like the fact that Bob has found a solution and I appreciate that he shared it. Now everyone commit it to memory.

All hardware consultants would be well advised to seek out an experienced installer and hang out with that person for a few hours in the field and glean as much info as possible.

I have spent some time with installers and I have several that I call with questions. Very enlightening!

I after 30 yrs in the trade have Never heard of beveling a hinge edge

..but I am on a job where all edgges are ….bad idea all the way around…the same company made the doors and jambs…there is almost 3/8 on left and 0 margomg on strike side actually hots the jamb…I installed the jamb…doesn’t get any truer…. Poor design and a worse idea

I’ve had people doing this for 30+ years and did not know the some hinges have Ball Bearings built into them and are required on fire rated openings.

And the 3 degree bevel edges is a small detail that is hard to notice but makes a huge performance difference.

I usually always go with a beveled hinge edge and standard hinges. That puts the gap on the hinge edge at about 1/8″ which is where I want it since the frame is often bowed in about 1/16″ in the middle after sheet rock is inserted. This clearance together with the beveled edge allows room for the door gasket and lower the resistance to closing and latching which is critical for low opening forces and ADA. Typically we shim to compensate for door sag so the top hinge is shimmed to pull the door to the hinge jamb, and the bottom is shimmed to push the door out. Amount of shimming depends on weight of door.