There are two basic sets of code requirements for glazing in doors and frames. One set addresses the limitations on the amount and type of glazing that can be installed in a fire door assembly. The other set ensures that the glazing is impact-resistant when it is in a location where it could be subject to human impact.

There are two basic sets of code requirements for glazing in doors and frames. One set addresses the limitations on the amount and type of glazing that can be installed in a fire door assembly. The other set ensures that the glazing is impact-resistant when it is in a location where it could be subject to human impact.

Past editions of NFPA 80 were more specific about glazing used in fire door assemblies, but with the variety of glazing materials now available, the standard has become less prescriptive. For most types of fire doors, glazing is limited by NFPA 80 to the “maximum area tested” (except fire-protection-rated glazing in temperature-rise doors). For 3-hour doors, the standard imposes a limit of 100 square inches if fire-protection-rated glazing is used; fire-resistance-rated glazing can be larger if allowed by the manufacturers’ listings (this ShortCodes class covers fire protection vs. fire resistance). NFPA 80 limits the maximum size of each glass light to 1296 square inches with no dimension exceeding 54 inches, unless the manufacturer has tested larger lights.

Glazing materials used in fire door assemblies must be labeled for that purpose, and installed in labeled glass kits or in accordance with the listings of the door/frame manufacturer. Glazing in wood fire doors is now required to be installed “under label service,” which means that it must be installed at the factory or in a shop that is approved by the listing laboratory.

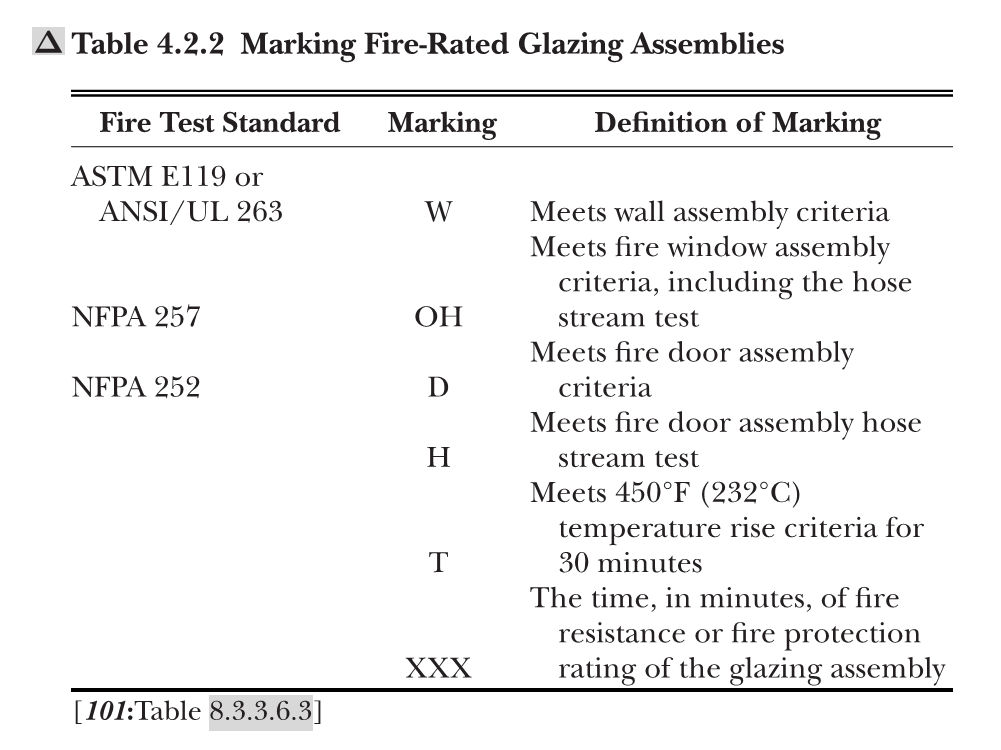

NFPA 80 includes prescriptive requirements for the labels required on glazing in a fire door assembly. Each piece of glazing must be labeled, and the labels must be visible after installation. Table 4.2.2 shows the required markings for each test standard. When glazing in fire doors needs to be replaced, it must meet the requirements of the current edition of NFPA 80, including the labeling requirements. The inspection of glazing, vision light frames, and glazing beads are included in the inspection criteria for fire door assembly inspections.

NFPA 80 includes prescriptive requirements for the labels required on glazing in a fire door assembly. Each piece of glazing must be labeled, and the labels must be visible after installation. Table 4.2.2 shows the required markings for each test standard. When glazing in fire doors needs to be replaced, it must meet the requirements of the current edition of NFPA 80, including the labeling requirements. The inspection of glazing, vision light frames, and glazing beads are included in the inspection criteria for fire door assembly inspections.

The second set of requirements – regarding impact-resistance – are found in the applicable building code or fire code. NFPA 80 simply states that glazing used in fire doors must meet all applicable impact safety standards.

The impact safety standards for glazing have been in existence since the 1970’s, but glazing used in fire doors was exempt from the requirements because compliant glazing was not readily available. There are now many glazing products which meet the requirements for impact resistance and fire protection, and revisions to the IBC were initiated by the father of a student who had been severely injured by traditional wired glass. The 2003 edition of the IBC removed the exemption for impact-resistant glazing in fire doors in educational occupancies. Further modifications were made in the 2006 edition, and glazing in fire door assemblies is no longer exempt from the impact-resistance requirements for any occupancy type.

Read this Decoded article for detailed information about the requirements for impact-resistant glazing, and then proceed to the review questions below.

Table: NFPA 80-2019

~~~

Review Questions

1. If an architect’s design calls for glazing larger than 100 square inches in a 3-hour fire door, what type of glazing must be used?

- Traditional wired glass

- Fire-resistance-rated glazing

- Tempered glass

- Fire-protection-rated glazing

2. Which of the following corresponds to a glazing label with the designation D-H-NT-90?

- Listed for a 90-minute fire door with the hose stream test, not temperature-rise-rated

- Listed for a maximum size of 90 square inches of glazing, used in a temperature-rise door

- Listed for 90 degrees of temperature rise, with hose stream

- Listed for use in a B-label fire window with a fire-resistance-rating

3. Which edition of the International Building Code (IBC) first required an impact-resistance rating for all glazing in doors in educational occupancies, including fire doors?

- 2000 IBC

- 2003 IBC

- 2006 IBC

- 2009 IBC

Answers: 1 – B, 2 – A, 3 – B